At first glance, sharpening chainsaws with your own hands is a rather difficult and long exercise, but with special grinding tools, this process will not be more difficult to sharpen other cutting tools. In this article we will talk about how to sharpen a chain of chainsaws.

At first glance, sharpening chainsaws with your own hands is a rather difficult and long exercise, but with special grinding tools, this process will not be more difficult to sharpen other cutting tools. In this article we will talk about how to sharpen a chain of chainsaws.

Content

- 1 The principle of operation and the dullness of chain links

- 2 Angles and parameters of links

- 3 Chain Sharpening Rules

- 4 Tools for sharpening chainsaw chains

- 5 Chain Grinding Machines

- 6 General conclusions

The principle of operation and the dullness of chain links

The chain link tooth has quite complex geometry. The upper and side cutting edges are inclined relative to each other at a certain angle, which makes the sharpening operation difficult. Planing wood with a tooth chain is similar to the work of a planer, and the thickness of the layer being cut is governed by the thickness of the stopper.

The chain link tooth has quite complex geometry. The upper and side cutting edges are inclined relative to each other at a certain angle, which makes the sharpening operation difficult. Planing wood with a tooth chain is similar to the work of a planer, and the thickness of the layer being cut is governed by the thickness of the stopper.

With intensive work, the saw teeth quickly become blunt. During the day, sharpening may be necessary several times. Especially exacerbated by the problem of meeting the chain with the ground. It is enough to hook the primer once for a couple of seconds with the tire, and you need to stop working due to the fact that the saw stops diving itself into the wood and the chips become rather small.

The more often you sharpen teeth that have become dull, the less material you will have to remove when sharpening the chainsaw chain, and it will last longer. Determining that it's time to sharpen is easy enough. The easiest way to do this is to listen to your sensations when cutting: a properly sharpened and sharp chain is drawn into the notch with a little pressure, and if you have to make an effort, the teeth will become dull. Also understand that the chain is time to sharpen, you can the size of the chips, inflying out of cut. Long thick chips can be only with a sharp chain, and small indicates that it is time to sharpen the chain.

Work chainsaw with a blunt or defective chain is not recommended. The result of her work can be fatigue in her hands and torso and poor cutting results. It also entails a strong decrease in performance, increased wear on all parts of the chainsaw and greater fuel consumption.

Angles and parameters of links

Proper sharpening of the chainsaw chain is impossible without knowledge of the link parts and the angles at which they should be sharpened.

Proper sharpening of the chainsaw chain is impossible without knowledge of the link parts and the angles at which they should be sharpened.

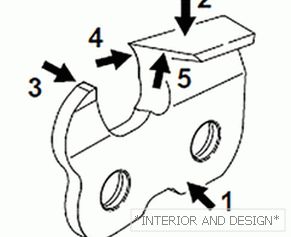

The main parts of the cutting link:

- Reason

- Tooth blade

- Depth stop

- End blade

- Upper blade

Upper blade angle, rake angle and sharpening angle may vary with sharpening. These angles greatly affect the cutting properties of the chain. It is advisable to observe the recommended values of these angles.

Each cutting link in front of the tooth blade has a depth stop. The difference in height between the leading edge of the back of the tooth and the highest point of the depth gauge is called the distance of the depth limiter. From this distance depends on the depth at which the upper blade will cut into the wood and, consequently, performance. This distance is set depending on the type of performance and pitch of the chain. Its average value is 0.6 mm and can vary in both directions by 0.2 mm. The consequence of higher values of this parameter will be a greater tendency to kickback, too much grip and vibration of the chainsaw. And its low values will lead to a loss of performance.

With each subsequent sharpening of the chainsaw due to a decrease in the top edge of the tooth, the height of the cutting chips decreases, therefore, every 5–10 sharpenings the depth limiter needs fileing.

Main corners of chain links:

-

The depth to which the upper blade cuts into the wood regulates its back angle. It is formed from the back of the tooth falling at an angle back.

The depth to which the upper blade cuts into the wood regulates its back angle. It is formed from the back of the tooth falling at an angle back. - The back angle of the end blade is formed from a tooth-tapering back blade. Its purpose is lateral cutting of chips.

- The rake angle is formed from the edge of the end of the blade relative to the sliding surfaces of the cutting unit. Different circuits, this angle may vary from 60 to 85 degrees.

- The back angle determines the amount of inclination of the upper blade back and is measured from the sliding surface of the cutting link. And different chains can have values from 50 to 60 degrees. The main blade of any link in the chain is the top one, and the back angle of the top blade is the most important angle. This angle is quite difficult to measure, but if other prescribed values are observed, it is formed correctly.

- Angle of sharpening or angle in the plan is the angle from the perpendicular to the guide rail to the upper cutting edge. It can be changed depending on the type of wood you are going to cut. A larger sharpening angle increases the cutting performance of soft, non-frozen wood, and a smaller value allows cutting hard and frozen wood more smoothly and with less vibration. However, sharpening angles less than 25 and more than 35 degrees are not recommended. As an exception, chains for longitudinal cuts are produced, the angle of which is 10 degrees.

Chain Sharpening Rules

Since the internal contour of a tooth is in its form close to circumference, and the chain is made of fairly soft metal, sharpening is made with a round file having a small diameter. For correct sharpening of the chainsaw, you need to accurately position the file relative to the tooth. The upper edge of the file relative to the top edge of the tooth should protrude approximately 1/5 of its diameter. Before sharpening, find out the parameters of your chain, since the diameter of the file is selected depending on the chain pitch. Usually it is 4–5.5 mm.

In addition to all of the above, for proper sharpening, it is necessary to observe file tilt angles. It should be at a right angle to the chain in a vertical plane and, as described in the paragraph “Angles and parameters of links” of this article, 30 or 10 degrees - in the horizontal. It is extremely difficult to fulfill these conditions only with the help of a file, so when sharpening the chainsaws use special tools that allow you to observe the correct sharpening parameters. Typically, these kits come bundled with chainsaws or can be purchased at almost any hardware store selling power tools.

Tools for sharpening chainsaw chains

The most common set for sharpening the chain includes a round file on a special holder, a flat file to reduce the depth stop, a template for the last operation, and a hook for cleaning the chainsaw from sawdust.

The most common set for sharpening the chain includes a round file on a special holder, a flat file to reduce the depth stop, a template for the last operation, and a hook for cleaning the chainsaw from sawdust.

The lines that are on the holder with a round file allow the tool to be correctly positioned relative to the chain. According to the orientation lines the holder is placed on the tooth to be sharpened. It lies on the top edge and depth stop, and the file is under the cutting edge.

The toolholder allows the file to be attached to the tooth at the correct height. For chains with different pitch, there are different holders. Choosing the right holder and the correct file diameter will allow the latter to protrude 1/5 of its diameter over the back of the tooth. We strongly recommend sharpening chainsaw chains to use only special files.

Before starting sharpening it is desirable to fix the tire. When working, it is necessary to make 2-3 turning movements from oneself, while tightly pressing the file to the edge of the tooth and not changing the position of the holder. Do not press the file too hard. move it smoothly and measuredly. The file should be rotated regularly to avoid clogging and unilateral wear. With this operation, all other teeth are also sharpened. For greater convenience, first sharpen all the teeth in one direction, and then the teeth in another direction.

While sharpening your teeth, try to keep the pressure and the number of movements the same for each tooth. Due to this, the teeth will have the same length. In the opposite case, the chain will have an uneven course and cracking is possible in it. The difference in tooth size can be eliminated by filing all the teeth up to the shortest length.

After 5–10 teeth grinding, you need to grind depth stop. For this, a template is used. It is placed so that the limiter protrudes from the slot, and this protruding tip is ground off with a flat file.

The design of the other set is different, but the principle of its operation differs little from that described above. It uses all the same round and flat files, and the universal special template allows you to properly sharpen the cutting tooth and depth stop. In case of sharpening the cutting tooth, the chain should fall into its slot. The file is superimposed on the template and fed under the cutting edge, based on the guide rollers. The file should move along the side edges of the template.

Before grinding down the height limiter, think about what kind of wood you will be cutting in the near future. For soft wood, the limiter is inserted into the slot with the words “Soft”, and for hardwood trees - into the slot with the words “Hard”. Sewing down the height limiter, as with the use of the first device, should be done with a few smooth movements of the flat file.

Chain Sharpening Machines

If the chain quite plowed gravel or sandy soil, it is unlikely to be able to sharpen it with a file. Also sharpening a file does not help with heavy chain wearbecause she lost her form. In such cases, it makes sense to use special machines. Such machines are divided into electric and manual.

If the chain quite plowed gravel or sandy soil, it is unlikely to be able to sharpen it with a file. Also sharpening a file does not help with heavy chain wearbecause she lost her form. In such cases, it makes sense to use special machines. Such machines are divided into electric and manual.

An electric machine is the best tool for sharpening chains. It is universal and has many settings and advantages, such as:

- setting the chain at the right angle;

- liner drive exactly to the sharpened edge;

- automatic clamping vise when the disc is lowered onto the chain.

However, its only disadvantage is the high price. His purchase is advisable only for workshops and enterprises engaged in the extraction of wood.

Manual machines also give a good result of sharpening, and the price of some of them can be commensurate with the devices described above. The principle of their work, we describe the example of two models of manual machines, manufactured by Stihl.

The design of these devices resembles an archery saw, which has a file instead of a blade. The model called "FG 1" is installed directly on the chainsaw tire, and "FG 2" is stationary. These machines are good because you can not only sharpen the chain, but also fit them to the size of the smallest tooth. Although the tuning mechanism is rather heavy, it allows you to sharpen the chain with any teeth parameters and save this setting for subsequent teeth and chains. It also allows to make teeth ideally identical each other.

General conclusions

Summing up, let's say that if your chainsaw chain is blunt, then you should not immediately carry it to the workshop for sharpening, because it can be done at home with your own hands. You only need to buy a set for sharpening or a special machine in the nearest store selling chainsaws and this purchase will soon pay for itself.