Wood construction is currently at its peak of popularity, and the lumber market is replete with various offers: log (rounded, chopped), timber (plain and profiled, solid, massive and glued).

Manufacturers are changing the technology of drying and processing to give lumber additional properties and eliminate the disadvantages inherent in natural wood. As usual, the introduction of corrections, which are designed to improve certain properties, may have a negative impact on other characteristics of the wood.

One of the popular materials is a profiled bar, which has such characteristics as:

- linear stability;

- strong joining of bars, which excludes the occurrence of mezhventsovy cracks and leakage of moisture;

- good thermal insulation properties;

- ease of installation;

- esthetic appearance;

- acceptable combination of quality and cost;

- long period of operation.

Note that these advantages are typical for all types of processed timber. Nevertheless, one of the most heated debates that flare up around the topic of choosing a tree for building a house is the comparison of profiled solid and glued timber. Opinions differ, there are many reasons for arguing the advantages and disadvantages, all other things being equal.

Glued laminated timber или профилированный брус — что лучше выбрать?

Let us analyze the characteristics and properties in order to find out what is the difference between these materials, made from one raw material according to similar technology, comparing them in a number of parameters:

1. Feedstock

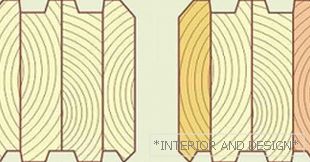

Profiled timber — изготавливается из цельного массива древесины. Feedstock проходит отбраковку, затем длительный процесс естественной или камерной сушки, повторный осмотр на наличие дефектов и обработка на профилирующем оборудовании.

Glued laminated timber — производится путем склеивания подготовленных, высушенных в камере, ламелей. Такой подход позволяет снизить процент брака, за счет возможности устранить дефект на части ламели. А также исключить растрескивание и скручивание древесины.

The combination of layers of timber from pine, larch, cedar--> Combining layers of timber from pine, larch, cedarFor the manufacture of timber used from two to five slats. This allows the manufacturer to vary the price also due to the use of different wood species.

Combining layers of timber from pine, larch, cedarFor the manufacture of timber used from two to five slats. This allows the manufacturer to vary the price also due to the use of different wood species.

For example, the central lamellae can be made of pine, and the front, of larch or cedar.

2. Sizes of timber

The dimensions of the profiled bar are limited by the length of the wooden blanks. The standard length of a bar, as a rule, is 6 m. or multiples of 2 and 3 mp

The standard sections include: 100x100, 150x150, 200x200. Manufacturers offer non-standard sizes, made for a specific project, but their cross-section rarely exceeds 200x200, which is associated with the complexity of drying. The thicker the array, the more difficult it is to ensure uniform drying.

The dimensions of the glued laminated timber vary over a wider range, and the maximum width reaches 275 mm. Due to the fact that the lamellae can be spliced in length, in some cases, the length of the laminated timber can reach 18 m. P. This length is made to order, (transportation to the construction site and the complexity of working with a long beam, imposes its imprint on its length).

Note that the greater the width of the beam - the higher the thermal conductivity of the structure.

3. Environmental friendliness

The eco-description is the main argument in the dispute about the difference between profiled and laminated timber and which one is safe for humans and the environment.

The main focus is on the fact that in the production of glued laminated timber used glue, which contains chemical compounds. Lamels are glued together with the use of polyurethane or polyvinyl acetate glue. Opponents of laminated veneer lumber, this gives grounds to assert that the eco-friendly cleanliness of laminated veneer lumber has to be forgotten.

However, adhesive mixtures are not homogeneous in composition and are classified from hazardous (FC2) to safe (FC0). Manufacturers of timber are required to provide a document containing information about what kind of glue was used in production, and confirming the level of formaldehyde.

It should be noted that the profiled beam also undergoes additional processing with antiseptics and fire retardants. In addition, in the manufacture of timber, only the inside of the log is used, which is freed from the protective bark and is more loose. This means that in order to preserve the performance characteristics of a profiled timber house, its walls must be periodically re-covered with special compounds designed to protect the wood from the harmful effects of ultraviolet radiation and other atmospheric phenomena.

4. Air Exchange

The vapor permeability of a profiled bar corresponds to the indicator for the type of wood from which it is made. Also, solid wood retains the ability to maintain a favorable microclimate, which is very important for a private house.

In the glue bar, this figure is much lower, because The lamellas are located in different directions, and there is also an adhesive layer that prevents partially free movement of air through the pores of the wood.

5. Humidity

The natural moisture content of wood depends on the breed and the time of year of harvesting and can reach 40-50%. But, suitable for construction material with a moisture content not higher than 15% +/- 3% (for exterior work, according to GOST 8486-86).

To reduce the level of humidity, as well as to avoid torsion and cracking of wood, manufacturers subject the timber to drying: natural or forced (in cells). The drier the timber, the less shrinkage will be given by the building constructed from it.

The optimum moisture content of glued timber - 11-14%, profiled - 15-18%. But, note that over time, both types of timber will draw moisture from the external environment and gradually their indicators will be approximately the same.

6. Shrinkage

Показатель, производный от влажности. Glued laminated timber дает усадку 0,4-1%, профилированный брус камерной сушки — 3-5%, естественной сушки — до 8%.

7. Strength

According to this indicator, glued exceeds profiled, because for its production, more dense lamellas cut from different parts of the log (cores, heart-shaped rays, tree rings) are used;

8. Deformation

Torsion bar when properly stored is excluded. As for the appearance of cracks in an already finished structure, the probability of their appearance is preserved for both types of timber, both profiled (width no more than 1 mm) and glued (depends on the quality of gluing).

9. Biological sustainability

Both types of timber are processed in the manufacturing process with special protective compounds. Therefore, the likelihood of fungus, mold or wood bugs is minimal.

10. Fire safety

Glued laminated timber горит гораздо медленнее, этот фактор очень важен для бани.

11. Aesthetics

Profiled and glued laminated timber has a high quality surface finish, which allows you to do without additional finishing, both internal and external. However, often, construction is carried out with a bar 150x150 mm thick and there is a need for additional warming.

As for the installation of window and door frames, the warm contour of the house, built of laminated veneer lumber, can be performed immediately after construction (assembly). But the profiled shrinks - you need to wait up to six months or use casing boxes.

12. Price

If we compare the initial costs, the cost of profiled timber is 30% lower than the price of glued laminated timber. But, in the course of operation, higher costs are required to maintain the appearance of the house from a profiled bar.

13. Probability of counterfeit

Profiled timber продается в больших объемах. Профилировать брус можно в кустарных условиях. Возможность надежного монтажа предоставит только материал, изготовленный на высокоточном оборудовании. Сделать контрафакт клееного бруса сложнее, т.к. трудно обеспечить процесс склейки ламелей.

Which is better, profiled or glued laminated timber? Table

Summary data on compared parameters (what to choose, which timber is better, what is different and which one should be used for building a house) are listed

| Parameter | Profiled timber | Glued laminated timber |

|---|---|---|

| Feedstock | Solid wood | Prepared pressure bonded lumber |

| Drying | Natural or chamber | Chamber |

| Sizes of timber | Maximum section 200x200 mm. Maximum length - 6 m. | Maximum section 275x275 mm Maximum length - 18 m. |

| Environmental friendliness | Does not contain harmful substances | The content of harmful components in the adhesive composition is within acceptable limits. |

| Air exchange | Natural to the wood | Broken |

| Humidity | 15-18% | 11-14% |

| Shrinkage | With chamber drying - 3-5%. With natural drying - up to 8%. | 0,4-1% |

| Strength | Low | High |

| Deformations | Allowed with a width not exceeding 1 mm | Likely. Depends on the quality of bonding |

| Biological resistance | High | High |

| Fire safety | Average | High |

| Aesthetics | Average. Могут встречаться мертвые сучки и темные пятна | High |

| Finishing work | 0.5-1 year or use casing | Immediately after construction |

| Loss of properties during operation | Cracks requiring caulks appear | Not |

| Price | 30% lower than glued | High |

| The probability of counterfeit (fake) | High | Insignificant |

As you can see, the question of what is better, glued or profiled timber, does not have an unequivocal answer, and the choice has a rather high degree of subjectivity.

The main thing is to determine what to use for home, cottages or bathhouses, buy a bar from a reliable manufacturer or a reputable supplier, to avoid purchasing low-quality lumber, as well as to entrust the work to professionals, or perform it yourself, according to the installation instructions.