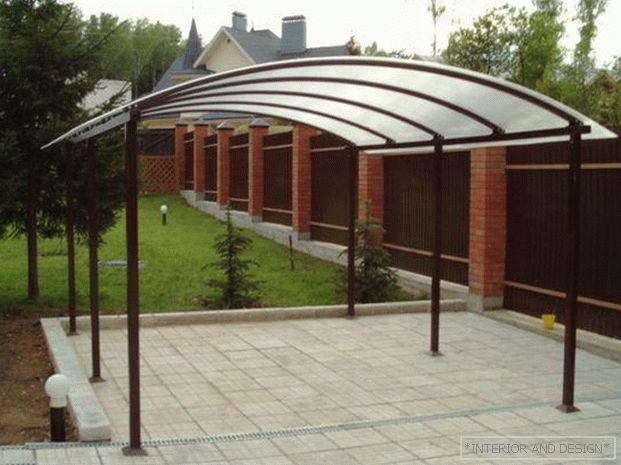

Sheds made of polycarbonate are a group of various structures, which include sheds over the loggia or balcony, sheds over the parking lot or sheds over the pool. In addition, canopies or visors from this building material are used as an element above the entrance to the house or above the porch, as a roof for a playground, as a covering of the storage area for various goods or materials.

Sheds made of polycarbonate are a group of various structures, which include sheds over the loggia or balcony, sheds over the parking lot or sheds over the pool. In addition, canopies or visors from this building material are used as an element above the entrance to the house or above the porch, as a roof for a playground, as a covering of the storage area for various goods or materials.

Polycarbonate canopies are especially demanded among summer residents and home gardeners. Products of this type are able to provide high-quality protection of the object from weather vagaries and precipitation, and perfectly honored aesthetics of the appearance of the entire site. In addition, the widespread sale of polycarbonate, a wide range of colors, low prices and the ability to self install they add attractiveness in the eyes of the consumer.

Content

- 1 What is polycarbonate?

- 2 Polycarbonate: advantages and disadvantages

- 3 How to choose a canopy made of polycarbonate

- 4 Installation instructions for polycarbonate shelters

What is polycarbonate?

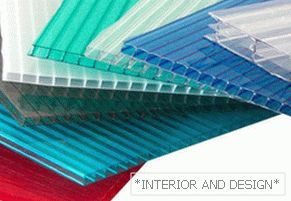

Polycarbonate — это особый материал строительного назначения, внешний вид которого создает the illusion of fragility and weightlessness. However, this apparent ease is provided by the unique indicators of sheet strength. One layer of polycarbonate more than 7 times stronger than plastic or PVC and glass 200 times stronger! This material is not only reliable and durable, it is, moreover, capable to elevate any territory in front of the house or in another area of the site. Some types of polycarbonate do not fade when exposed to direct sunlight, and the presence of a protective anti-corrosion coating on each unit of the product provides its additional resistance to wear.

Polycarbonate can be honeycomb or monolithic. This building material is used for the manufacture of:

-

canopies;

canopies; - the gate;

- canopies;

- carports;

- fences;

- greenhouses;

- arbors.

Build any such a construction it is possible both with the help of special firms that specialize in working with polycarbonate, and with their own hands.

Polycarbonate: advantages and disadvantages

The main properties and characteristics of this material have earned him consumer confidence and became the cause of its wide distribution. The combination of many positive properties make it every day all more popular among the population.

The positive features of polycarbonate are:

-

small weight;

small weight; - impact strength;

- ease of assembly and installation;

- high plasticity;

- resistance to thermal effects;

- good degree of transparency;

- good indicators of resistance to the effects of biochemical and chemical substances.

Polycarbonate sheets possess low thermal conductivity due to the fact that the material is made in the form of honeycombs, which are a kind of cavity. Each such cell is equipped stiffeners and filled with air.

Polycarbonate hinged products are light but very durable metal structures. These indicators are their main advantages in comparison with canopies from other materials. Low weight Such a coating does not exert strong pressure on the bearing elements of the structure and can do without an additional increase in the strength of the substrate.

The disadvantages of polycarbonate include such indicators as:

- exposure to abrasive effects;

- tendency to thermal expansion;

- susceptibility to ultraviolet.

Recently, however, an increasing number of manufacturers are trying to produce sheets of this material. with a special protective coating from sun exposure. Such a film firmly adheres to the sheet and ensures its appearance for many years. Thus, the question of susceptibility to UV rays reduced to zero.

As for thermal expansion, taking into account this peculiarity of the material, constructing a structure from it, it is enough small gap, which solves this problem. And those scratches that can be applied to the surface of the polycarbonate formation during transportation or working with it are almost imperceptible.

In other words, the number of positive features of polycarbonate many times exceed its shortcomings, which, moreover, are quite amenable to adjustments.

How to choose a canopy made of polycarbonate

The types of canopies of this material are divided into:

- constructions open and closed type;

- they can be detached or adjacent to different buildings and buildings.

Shedные изделия из поликарбоната — это и крупные constructions и элементы малых архитектурных форм. Дизайн большинства навесов отвечает current trends and has an attractive look.

Choosing polycarbonate, you should focus not only on its color, but also by thickness and radius bending. Important and indicators of resistance to snow and wind loads. Large role in the selection of suitable material parameters play construction purpose and its size, as well as the planned step of crates.

It should be remembered that too thin sheet requires small step of crates, otherwise the roof may be deformed. The presence of this threat requires more metal profile, which, in turn, requires in additional supports which together increases the cost of overhang.

Excessively thick polycarbonate has low flexibility and becomes the cause of unreasonable financial expenses for more durable frame components.

Those who are thinking about making a carport for their car or for other purposes with their own hands, should know that such a structure is simple construction from polycarbonate sheets, which are mounted on metal shaped pipes. That is, to make an independent installation of the product, subject to certain requirements and the necessary successive stages in the work, you can high quality and fast.

Installation instructions for polycarbonate sheds

To make a canopy of polycarbonate sheets, first of all you need to make a drawing and a project. Also an important component of the initial phase of work is budgeting. To finally determine the type of construction, you need to draw on paper a few approximate diagrams. The one that most will meet your wishes and abilities will be the starting point in drawing up detailed drawing.

To make a canopy of polycarbonate sheets, first of all you need to make a drawing and a project. Also an important component of the initial phase of work is budgeting. To finally determine the type of construction, you need to draw on paper a few approximate diagrams. The one that most will meet your wishes and abilities will be the starting point in drawing up detailed drawing.

If you can not boast of the presence of engineering experience, you will have to be patient, since you will not be able to make a qualitative sketch immediately. In order to reduce extra costs to a minimum it is necessary to calculate and measure everything accurately for several times.

- If you are planning to build a canopy, which will adjoin the house, then preparing the foundation of a solid metal profile framework will not need. With the help of a welding machine, a grinder and a drill, it will be possible to create a skeleton corresponding to the preliminary calculations. The finished construction is made of a light metal frame, attached with anchors to the wall surface.

- In order to fix the sheets of polycarbonate, use special mounts. The sheets themselves are laid in such a way as to comply rectangular perimeter. Additional stops, installed parallel to the wall surface, will add strength to the finished structure. However, it is necessary to remember the need for accurate calculations, since excessive load can provoke exit from the wall mounting bolts.

Separate carport device will require high costs as time, effort, and finance. It would not hurt the help of friends or households. In the event that it is planned to build a carport, it will be easy to determine the required dimensions. Knowing exactly what you need and doing everything preliminary calculations and markup, you can get to work.

- First of all, you should take care of the arrangement foundation. The massive canopy structure requires a solid base. After preparing the foundation, you can proceed to the installation of supports made of metal, which must be at least four.

- A frame (made of wood, shaped tube or metal corners) is fixed on the fixed and fixed supports. In that case, if you plan to carry out the lighting in a canopy, then calculating the components of the load, take note of this fact.

- At the last stage of the work, sheeting is done with sheets that are fastened with special devices.

Make a canopy of polycarbonate do it yourself everyone can This work is especially easy for those who are accustomed to physical labor, and independently ennobles their own house and site.