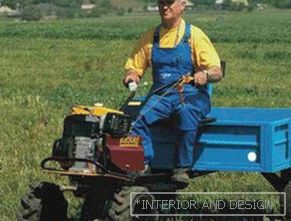

The motor-block - the universal agricultural car, very necessary in a personal farm. It can be used to transport various things: tools, country garbage, seedlings, crops, they can mow the grass, remove snow in winter, and also plow the land.

The motor-block - the universal agricultural car, very necessary in a personal farm. It can be used to transport various things: tools, country garbage, seedlings, crops, they can mow the grass, remove snow in winter, and also plow the land.

You can buy a walk-behind tractor in a regular store, just like a trailer for it. But you can save a little - make your own trailer.

Content

- 1 Types of tillers

- 2 DIY Trailer

- 3 Multifunctional trailer do it yourself

Types of tillers

Motoblocks taken classified by power. The greater the area of the suburban area, the more powerful the device should be purchased.

- Amateur or light tiller.

- Medium tillers.

- Heavy motor cultivators.

Amateur or lightweight tractor is a great choice for a small suburban area, so it has a capacity of up to 3.5 liters. with. Ultra-light motor-cultivators with a capacity of not more than 1.2 liters are distinguished from this group. with. and weighing up to 12 kg. They have only one gear and a milling cutter, the grip of which does not exceed 25 cm. Ultra-light tillers extremely comfortable to carry with you in a transport or train, but by their functional purpose in the country they play the role of chopper - they treat the top layer of soil, loosen it and remove weeds.

Amateur or lightweight tractor is a great choice for a small suburban area, so it has a capacity of up to 3.5 liters. with. Ultra-light motor-cultivators with a capacity of not more than 1.2 liters are distinguished from this group. with. and weighing up to 12 kg. They have only one gear and a milling cutter, the grip of which does not exceed 25 cm. Ultra-light tillers extremely comfortable to carry with you in a transport or train, but by their functional purpose in the country they play the role of chopper - they treat the top layer of soil, loosen it and remove weeds.

Motoblockи легкого типа отличаются большей шириной захвата — около 40 см, и мощностью, а также значительным весом — около 25 кг. Такой мотоблок является alternative to shovels, he can dig the ground deep. The advantages of amateur cultivators are:

- low price;

- ease of use;

- high tillage rate.

Of the minuses can be identified:

- a small range of tasks;

- as well as the fact that such tillers are suitable for processing a small area.

Medium tillers suitable for areas of no more than a hectare. Engine power of motor-cultivators from 3.5 to 5.5 liters. with., weight about 50 kg, width of capture - up to 90 cm.

A distinctive feature of the average motoblocks - availability of reverse gear. This means that you can easily unfold on the site.

All middle tillers have a frame to which you can attach:

- plug;

- various paws;

- disk hiller;

- boron et al.

With the additional accessories, the tiller becomes indispensable assistant - he plows the soil, digs up the crop (potatoes, carrots, beets), removes weeds, performs hilling and harrowing.

Heavy motor cultivators fit for large areas. They are very heavy - about 100 kg, grip width more than 100 cm, power from 9 liters. with. These tillers are used by farms and utilities.

DIY Trailer

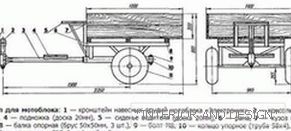

The simplest tiller useful for transportation seedlings, crops, crates and long loads. For its manufacture will need the following materials:

-

steel sheet no more than 2 mm thick;

steel sheet no more than 2 mm thick; - several pipes made of steel with dimensions of 60 * 30 mm and 25 * 25 mm;

- fastener elements;

- screwdriver;

- springs, wheels - possible from the old car;

- jigsaw and grinder;

- 2 mm dural sheet;

- welding machine;

- channel number 5.

The process of creating a trailer begins with the manufacture of the frame. For this you need to make 2 traverses - back and front crossbar. They can be made from a corner 25 * 25 cm. Also need spars that can be made from conventional pipe the size of 60 * 30 mm. Finished elements must be connected by five crossbars - you will get a frame lattice.

Next to the pipes you need weld 4 racks, To the top of which is additionally attached strapping from the corners of the size of 25 * 25 mm.

Next to the pipes you need weld 4 racks, To the top of which is additionally attached strapping from the corners of the size of 25 * 25 mm.

In order for the motoblock to have folding sides, you need a frame separate from the frame designs. The resulting grid must be strengthened with dural sheet, which is bolted. Sewing is made with thin sheets of metal, which are attached to the uprights and straps by welding.

Two channels of the same size you need insert each other One of the ends to add with wheel axles. Get beams. It should be attached to the side member - the springs should be put on the axis of the bracket and the earrings, the center should be welded to the beam.

For the manufacture of the drawbar, you can take a pipe size of 60 * 30 mm rectangular shape. Front ends need weld to the body motoblock, rear - to the front of the spar, leaving an overlap of about 200 mm.

Multifunctional trailer do it yourself

If you are well versed in technology, you can try to make functional trailer.

-

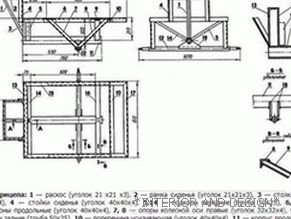

First needed decide on the design. You can use the finished drawing or develop a new one. Pay attention to the capacity and size of the structure; the trailer must contain at least 6 bags of crop weighing from 400 kg

First needed decide on the design. You can use the finished drawing or develop a new one. Pay attention to the capacity and size of the structure; the trailer must contain at least 6 bags of crop weighing from 400 kg - After calculating the required dimensions count the number metal rolling and channels.

- For the manufacture of the trailer you will definitely need welding machine, usually do not succeed by screws.

- For frame construction use metal corners 40 * 40 or 50 * 25 mm, trimming rectangular and round pipes. For the body will need a bar 50 * 50 mm and a few 20 mm boards.

- If you decide to take the path of least resistance, you can take as a basis finished structure trailer. It differs in the increased durability, and it means that such trailer will be suitable for a relief surface.

- The design of the trailer to the motorblock consists from 4 elements: wheels, frame, carrier and body. All nodes are connected by welding.

- The body is made of boards, on the corners of which corners are fixed. It is attached to the frame by means of support beams - 3 beams made of wood.

- The frame will need steel pipes, rods and angles.

- Since this construction is uniaxial then the load in it should be distributed as follows: the center of gravity should not extend beyond the axis of the wheels, while it is shifted forward.

- For the manufacture of running gear need springs and wheels. Of course, you can buy new ones, or you can take them from an old car.

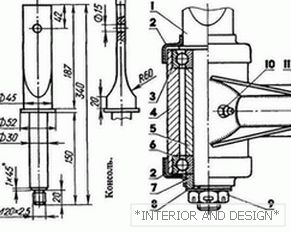

- For a wheel axle, a 30 mm steel bar of such length will be suitable, at which the wheel will not protrude beyond the rim of the body. It must be attached to the side members and the longitudinal hinge through corner supports and kerchiefs.

- Motoblock connects to the trailer using the console. Since it is attached directly to the bracket, its top should follow the shape of the derrick shaft. The bottom of the console is an axis with a rotating swivel carrier.

- Dishl need to insert in the longitudinal hinge and secure the thrust ring. In this case, the trailer wheels will turn independently from the wheels of the moto-cultivator.

- The last step in making your own trailer - installation driver's seat and running boards.

Trailer готов. Как видите, изготовить его simple enough but it will bring truly invaluable benefits, will save not only time, but also your health.