Gardeners who regularly tidy up their site know how much waste is left after such procedures. Of course, it would be easier to just throw it all away as unnecessary garbage, but a caring and economical summer resident will try so that nothing is wasted. The best way to simplify waste disposal is to use a garden shredder. This device easily grinds almost any natural source material.

Gardeners who regularly tidy up their site know how much waste is left after such procedures. Of course, it would be easier to just throw it all away as unnecessary garbage, but a caring and economical summer resident will try so that nothing is wasted. The best way to simplify waste disposal is to use a garden shredder. This device easily grinds almost any natural source material.

Garden shredder — очень useful and necessary thing for any summer resident. With it, you can grind such natural waste as twigs, paper, grass and leaves. Most often, such processing of raw materials is carried out in order to manufacture fertilizer for the site, the so-called mulch.

Content

- 1 Varieties of garden shredders design

- 2 Engine power and type

- 3 Video review of different types of shredders

- 4 Homemade chipper: the nuances of creating a device

Varieties of garden shredders design

Modern manufacturers offer a convenient and economical option for recycling. Garden shredders, or chippers, presented in a huge assortment, so buyers are quite difficult to determine the unit. Conventionally, devices are divided into types, by analyzing which, you can make the right choice. Each type of chipper is distinguished by certain characteristics or parameters.

Modern manufacturers offer a convenient and economical option for recycling. Garden shredders, or chippers, presented in a huge assortment, so buyers are quite difficult to determine the unit. Conventionally, devices are divided into types, by analyzing which, you can make the right choice. Each type of chipper is distinguished by certain characteristics or parameters.

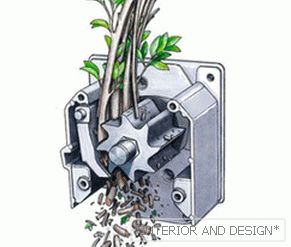

To understand the varieties of garden shredders, it is necessary to begin to understand how they work. Design any such unit has three components:

- receiving device;

- bunker;

- mechanism for cutting material.

In fact, the device chipper something resembles a meat grinder. The material prepared for processing is placed in a bunker, from where it falls to a moving knife disc.

Если углубиться в сам процесс измельчения отходов, то можно классифицировать chippers следующим образом:

- knife;

- milling;

- universal.

The first type of garden shredders as a cutting mechanism has metal diskon which knives are attached. Such chippers are designed for processing soft materials, such as grass or thin shrub stalks. The quality of knife shredders may vary depending on the material from which the blades are made, and the speed of the unit is determined by the engine power.

Milling chippers able to process harder raw materials than previous devices. With their help, ground dry branches, as well as various types of wood. However, such a unit is not suitable for grinding new materials. By design, milling devices have the most similar features to a meat grinder. A milling cutter having a cylindrical shape and six teeth is installed inside the main unit.

Milling chippers able to process harder raw materials than previous devices. With their help, ground dry branches, as well as various types of wood. However, such a unit is not suitable for grinding new materials. By design, milling devices have the most similar features to a meat grinder. A milling cutter having a cylindrical shape and six teeth is installed inside the main unit.

Universal Grindersas the name implies, are considered the most profitable units. They combine the two previous types of cutting mechanisms. Due to this, universal shredders are most effective in work when compared to milling and garden ones.

Engine power and type

In terms of power, the chippers are also divided into three types:

- devices for domestic use;

- average performance units;

- professional shredders.

Household chippers have low power, no more than 2200 watts. However, the price of such shredders is quite consistent with their capabilities - manufacturers offer units that are temptingly cheap. Buy an amateur chipper can afford almost every summer resident. However, with the help of such a device, it will be possible to grind only grass. The unit operates with a relatively low grinding ratio of 5: 1.

Middle class chippers allows you to effectively recycle waste from large areas planted with shrubs and trees. Power these devices often comes up to 4 kW and the cutting mechanisms are more refined. With medium shredders, you can grind hardwood and fruit. Such units can not be called budget, but they do an excellent job with the task, without causing problems. The chopping ratio of middle class chippers is higher than the value for household appliances. The devices grind waste, grinding them 8 times.

Professional units - Technique, almost no boundaries. They have such a high level of performance that they are able to cope with even the thickest and hardest branches. Professional chippers also grind cones and hard fruits along with seeds. They reduce waste about 10 times. In addition, professional devices often have additional features. Units can be equipped with options to adjust the speed of the blades, switch to automatic mode, or even lock the engine for safety.

Professional units - Technique, almost no boundaries. They have such a high level of performance that they are able to cope with even the thickest and hardest branches. Professional chippers also grind cones and hard fruits along with seeds. They reduce waste about 10 times. In addition, professional devices often have additional features. Units can be equipped with options to adjust the speed of the blades, switch to automatic mode, or even lock the engine for safety.

The last classification characterizing varieties of garden shredders is determined by type of motor device and it looks like this:

- electric models;

- petrol units.

Network powered chippers belong to class cost effective devices. In use, they do not have a high level of performance. Most often, electric garden shredders are produced as amateur appliances. The maximum size of the processed branches - 5 cm in length.

Petrol devices are usually presented as professional devices, but sometimes middle-class units are also equipped with this engine. Compared to electric shredders, these chippers emit too much noise in the work, which can be attributed to an undeniable minus.

Video review of different types of shredders

Homemade chipper: the nuances of creating a device

As it was already repeatedly said, the garden shredder is one of the main assistants of the summer resident. Of course, manufacturers have already realized it a long time ago and began to produce a huge number of various chippers. But anyway homemade equipment still not losing its popularity. There are two reasons for this. Firstly, self-assembly of a shredder will cost the consumer several times cheaper than purchasing a ready-made unit. The risk of a chipped chip breaker can also be attributed to this point - the factory device will require expensive and branded parts for repair. Secondly, self-made adaptation significantly differs qualitative characteristics. It more durable, does not require such care as a branded unit, and also copes even with complex work.

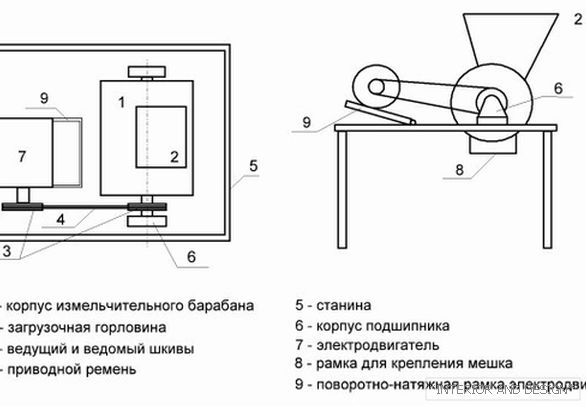

Homemade Garden Chopper изготавливается в several stages:

- ra axis sits down somewhat cutting discs with a short distance between them;

- further attached to it pump pulley (or VAZ removed from the generator);

- welding method is used to manufacture a metal frame on which the engine is placed;

- added to the structure stop bar;

- block of circular saws is covered with a protective cover made of sheet metal;

- joins the main body receiving device in the form of a bunker.

The engine for the homemade chipper can be borrowed from circular saw. It must be mounted on a metal frame so that, if necessary, you can adjust the tension of the drive belt. To do this, just do not attach the engine tightly. The "heart" of the shredder should move freely in relation to the saws.

Buy a ready-made chipper or assemble an improvised device is a personal matter of every gardener. In any case, the unit must be of high quality and have the same power level that will meet the conditions of its use.