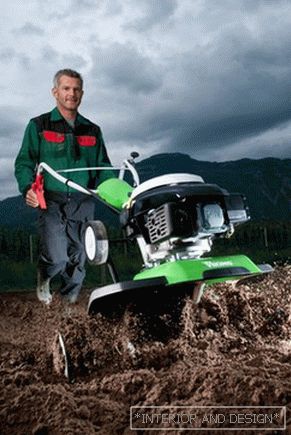

Processing of land for a person is associated with heavy physical labor. The special agricultural machinery - a cultivator can help to solve this problem with the maximum effect.

Processing of land for a person is associated with heavy physical labor. The special agricultural machinery - a cultivator can help to solve this problem with the maximum effect.

A cultivator is a tillage machine. By types of tillage machines can be divided into steam and tilled. Steam units are used for soil treatment before planting, tilled - for the treatment of already sown land.

The bulk of all models of cultivators has a total construction, which includes the following assemblies:

- рама и рабочие элементы (фрезерные ножи, paws, discs

etc. ); - wheels (running - at hook-on cars, basic - at hinged);

- fastening system of working elements (paw holders, plates,

etc. ); - mechanisms for changing the position of the unit from the working state to the transport;

- nodes that regulate the depth of the working parts;

- nodes to change the position of the working elements of the cultivator to the desired width of the aisle;

- steering gear to control the movement.

The working parts of the cultivating equipment include the following parts:

- paws (cutting weeds, loosening the soil, loosening and fertilizing, hilling);

- discs (smooth and cut-out - row spacing; rotation stars - crust destruction on the ground, loosening between the rows and protective zones; impellers - soil loosening and destruction of vegetation in forest zones with crop height up to 2 m; plants (up to 70 cm), planted on the bottom of the furrow).

Principle of operation The cultivating unit is based on loosening the soil with the help of special sickle-shaped knives. On the one hand, this unit does not cause any harm to the fertile layer of soil, on the other - as they say, "at the root" destroys weeds. The main function is performed by the cruciform paws: the lancet loosen the soil at a shallow depth, the loosening paws - for deep processing.

Content

- 1 Comparative analysis of different types and models

- 1.1 Petrol and electric cultivators

- 1.2 Mass classification

- 2 Особенности of choice модели культиватора

- 3 Rules of operation of cultivators

Сравнительный анализ разных типов и models

Modern manufacturers produce many different models, differing from each other in a variety of parameters.

Petrol and electric cultivators

-

Petrol units are suitable for work on sites of various area depending on engine power. The principle of operation of the gasoline cultivator is to bring all the elements into working condition by means of a drive from an engine whose power can reach 7 liters. with. The engine can be two or four stroke. Moreover, the latter has a significantly longer lifespan and does not require mixing oil and gasoline. For the convenience of control of the cultivator, all control buttons are displayed on the handle. During the operation of this unit there is practically no vibration.

Petrol units are suitable for work on sites of various area depending on engine power. The principle of operation of the gasoline cultivator is to bring all the elements into working condition by means of a drive from an engine whose power can reach 7 liters. with. The engine can be two or four stroke. Moreover, the latter has a significantly longer lifespan and does not require mixing oil and gasoline. For the convenience of control of the cultivator, all control buttons are displayed on the handle. During the operation of this unit there is practically no vibration. - Aggregates with electric engine used to work in small areas, in enclosed areas - flower beds, greenhouses, hotbeds - where gasoline devices cannot be used due to exhaust gases Electric cultivators have a small mass and are characterized by compact size. However, despite the low weight, the units are quite stable, which greatly facilitates the work with them. The principle of the mechanism - in setting in motion of working elements by means of an electric motor.

Mass classification

- Weight cultivators up to 30 kg. Such units have a rather low power, so it is preferable to use them for work in small areas. Such models are mobile and compact.

- Weight cultivators from 30 to 60 kgwhose capacity reaches 4−5 l. with., allow to use them on sites of the big area. The quality of the cultivated soil can be anything: both virgin and plowed fields.

- Weight cultivators more than 1 centner. The power of such units reaches 8 liters. with. and higher. This technique can be used for the treatment of heavy clay soils in large areas.

Concerning pricing policy, it all depends on the model and the intended operating conditions of the cultivator. Since electric models are mainly used in small areas and in premises, their prices range from 3,700 to 17,000 rubles. For gasoline models, this range is from 7800 to 32000 rubles. All will be depend from the power of the unit, its size and a set of attachments.

Особенности of choice модели культиватора

Treatment soil with the use of cultivating aggregates has a number of important nuances. The market for agricultural machinery currently offers a lot of various models, for example, a Tornado cultivator, so the choice of a cultivator for personal use can be quite problematic. Before you dwell on any one model, you need to evaluate the features of your site. If a plot part of the cooperative, it would be right to refer to the experience of neighbors. After all, the lands in one community have similar characteristics. Exceptions can be at significant differences in elevation on the plots. Even more likely differences in the characteristics of the soil on the slopes and hilltops from areas that were previously marshy.

Treatment soil with the use of cultivating aggregates has a number of important nuances. The market for agricultural machinery currently offers a lot of various models, for example, a Tornado cultivator, so the choice of a cultivator for personal use can be quite problematic. Before you dwell on any one model, you need to evaluate the features of your site. If a plot part of the cooperative, it would be right to refer to the experience of neighbors. After all, the lands in one community have similar characteristics. Exceptions can be at significant differences in elevation on the plots. Even more likely differences in the characteristics of the soil on the slopes and hilltops from areas that were previously marshy.

If a neighbors применяют культиваторы для обработки земли на своих участках, надо обратить внимание на количество прилагаемых оператором усилий. Кроме того, надо по возможности проанализировать качество обработки грунта: степень измельчения земляных комьев, глубину, ширину. Такая аналитическая информация может существенно облегчить процесс of choice как техники для обработки собственного участка, так и необходимого комплекта навесного оборудования.

Perfect an option would be a cultivator that moves along the plot to be processed without jerks, at an acceptable speed, and leaves behind a flat strip of crushed soil with a coma diameter on average ≈ 1 cm. The operator does not have to make great efforts when the unit is working. Its main function is maneuvering.

If the unit is periodically strong buries the operator is forced to pull him into the ground, or, on the contrary, the cultivator strives to “walk along the heights” without significantly tilling the soil, which means that the model is incorrectly chosen.

The basis of such of problems lies in the wrong ratio of the mass of the cultivator with the power of its engine and the quality and density of the treated soil. A heavy machine on soft ground will be buried in the ground, and light on clay soils, and even in dry weather, the operator will be forced to dig deep.

To prevent such problems aroseYou must first of all carefully approach the issue of the mass of the cultivator. If the unit is supposed to be used on soils with different density, it is possible to provide a model that allows you to additionally use hanging weights.

Rules of operation of cultivators

The cultivator is complex equipment that requires compliance with certain requirements and rules for its operation. Since the unit is equipped with sharp moving parts, it is possible to work on it only with good visibility, or, if the cultivator is operated indoors, with effective lighting.

The cultivator is complex equipment that requires compliance with certain requirements and rules for its operation. Since the unit is equipped with sharp moving parts, it is possible to work on it only with good visibility, or, if the cultivator is operated indoors, with effective lighting.

Before you start work, you need to familiarize yourself with instruction manual and follow all its instructions. Next, you need to prepare the site for processing, remove stones and other foreign objects. Be sure to make sure that there are no children and animals in the area. You must also ensure that the unit is in good condition and that there are no damages (chips, cracks

It is unacceptable to try to raise performance cultivator, deeply deepening the work items and increasing speed. This is fraught with loss of control of the unit and serious injury to the operator.

The worker must be attentive when working on hard ground. The cutter stuck in the ground will pull the cultivator forward. The operator in this case should release the handle and not make attempts to keep the cultivator.

If any of the moving work items outsider subject, operator actions should be as follows:

- stop the engine;

- disconnect the high-voltage cable from the spark plug (to prevent accidental starting);

- inspect the cultivator for damage.

If the engine suddenly appeared vibration, actions should be similar to those described above.

It is absolutely unacceptable to fill up fuel during operation or try to repair a running engine.

Further, if you do not plan to use the cultivator in the next 30 days, you must to merge all fuel and start the engine to produce gasoline residues. This should be done due to the fact that methanol and ethanol (the main components of gasoline) attract moisture. If you do not remove the remaining fuel, over time will begin the process of oxidation in the gas tank. Butter before conservation, the equipment must also be drained.

It is absolutely unacceptable to try to independently adjust the parameters of the engine and repair the carburetor without special qualifications.

Competently approaching the issue of choice cultivator for their own needs and observing the rules for operation, you can get yourself a reliable assistant for agricultural work for many years.