Recently, a lot of new materials have appeared on the market. One of the well-known and fairly common is polycarbonate. Quite a lot has already been told about its advantages. It is a translucent plastic, which is currently being actively used, which led to the gradual replacement of ordinary glass. This traditional material is used less and less in greenhouses. It is also less commonly used in capital construction.

Recently, a lot of new materials have appeared on the market. One of the well-known and fairly common is polycarbonate. Quite a lot has already been told about its advantages. It is a translucent plastic, which is currently being actively used, which led to the gradual replacement of ordinary glass. This traditional material is used less and less in greenhouses. It is also less commonly used in capital construction.

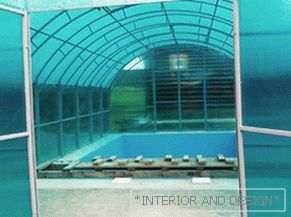

The main advantage of polycarbonate is its amazing flexibility, thanks to which it is possible to create structures of rectilinear and arched shape. Note that, along with flexibility, this material is also distinguished by high strength characteristics.

Another important advantage of this material is its excellent light scattering ability. This ensures that the sunlight that passes through the material does not burn young seedlings. Another advantage of this material is that it acts as an ultraviolet filter. Passing through it, solar radiation loses the component most dangerous for plants.

The excellent mechanical and optical characteristics of polycarbonate, as well as its versatility, contributed to the active growth in the production of this material. Currently, this material is produced in large quantities. In addition, manufacturers expand its range. There are currently many varieties of polycarbonate on the market that can be used for the device of greenhouses and greenhouses. In this regard, for many dacha owners, the question of which polycarbonate to choose has become an urgent issue.

Errors in the purchase of this material - not such a rare phenomenon. They are due to the abundance of types of this material, the presence on the market of a significant proportion of poor-quality polycarbonate, as well as a weak theoretical knowledge of summer residents.

Having decided to arrange a greenhouse made of polycarbonate on their site and not seriously approaching his choice, many acquire the material of the first manufacturer. This leads to frustration and high financial costs. In order not to face such problems, this article will further discuss how to choose the right polycarbonate for the greenhouse at the summer cottage.

Content

- 1 How to choose polycarbonate?

- 1.1 Dimensions

- 1.2 Thickness

- 2 Durability is an important selection criterion.

- 3 Polycarbonate Light - what is it?

- 4 Manufacturer selection

- 5 Conclusion

How to choose polycarbonate?

The peculiarity of the structure of this material provides him high strength and thermal insulation characteristics. It consists of two parallel plates of small thickness, which are connected by vertical and inclined stiffening ribs. Due to this, the structures created from this material can provide high strength. The presence of warm air in the cells in this material is due to the good heat-insulating properties of this material.

The peculiarity of the structure of this material provides him high strength and thermal insulation characteristics. It consists of two parallel plates of small thickness, which are connected by vertical and inclined stiffening ribs. Due to this, the structures created from this material can provide high strength. The presence of warm air in the cells in this material is due to the good heat-insulating properties of this material.

Dimensions

Currently on the market you can find polycarbonate, produced in the form of sheets with sizes:

- 2.1 x 2 m;

- 10,1x 6 m;

- 2,1x12 m

Note that most often on sale are the last two options. The first is extremely rare detect in hardware stores. Size is of great importance in practical terms, as it allows for accurate calculation of material consumption. This allows minimizing the loss of polycarbonate during cutting. Since for us the greatest interest is provided by polycarbonate, intended for the arrangement of greenhouses, the types of this material that are suitable for creating such structures will be discussed further.

Thickness

Another pressing question for consumers is how thick polycarbonate is best used for a greenhouse. Immediately, we note that the optimal choice for such tasks will be cellular polycarbonate with a thickness of 3.5 to 50 mm.

Another pressing question for consumers is how thick polycarbonate is best used for a greenhouse. Immediately, we note that the optimal choice for such tasks will be cellular polycarbonate with a thickness of 3.5 to 50 mm.

Before choosing this material, you need to decide for yourself which sheet thickness will be optimal for you to build a greenhouse. Here the main role is played by:

- snow and wind load factors;

- crate step;

- permissible bending radius of the material.

In order to determine this, it is not necessary to carry out complex calculations, since practical experience in using polycarbonate, as well as recommendations from manufacturers, give a clear answer to this question.

If the site owner plans to use the greenhouse in spring and autumn, then it is optimal to choose a material whose thickness is at least 6 mm.

Some summer residents want to grow plants in the winter, so they arrange a winter greenhouse. For her should pick up single chamber cellular polycarbonatewhose thickness is 10 mm. Also suitable for the construction of such structures two-cell polycarbonate. Its thickness parameter is 16 mm. The large thickness imposed on the material for winter greenhouses is due to the additional load in the form of snow masses, which accumulate on the greenhouse surfaces during the winter months.

On specialized resources, some summer residents offer small thickness materials as an inexpensive replacement for cellular polycarbonate. Its thickness is 4 mm. However, using such a polycarbonate, the cost of building a greenhouse increases due to the fact that the crate step has to be made more frequent. And this leads to the fact that the cost of construction of the structure increases significantly. In addition, the installation of the frame becomes more difficult. At the same time, some gardeners, who have saved on material thickness, complain that even at a step of batting 0.5 m from the snow load deformation of the sheets of material.

Durability is an important selection criterion

Having become acquainted with information materials about cellular polycarbonate and having learned about a large number of its advantages, many people have the impression that polycarbonate is a material that has only advantages, and it has no disadvantages. However, this is not quite true. Like any plastic, polycarbonate has poor resistance to solar radiation. Under its influence, its destruction occurs after a certain time.

Having become acquainted with information materials about cellular polycarbonate and having learned about a large number of its advantages, many people have the impression that polycarbonate is a material that has only advantages, and it has no disadvantages. However, this is not quite true. Like any plastic, polycarbonate has poor resistance to solar radiation. Under its influence, its destruction occurs after a certain time.

To cope with this minus, many manufacturers in the manufacture of their products on the surface of polycarbonate sheets cause special film layer. Thanks to him, the material is protected from ultraviolet radiation. Therefore, it is extremely important when mounting a greenhouse made of this material not to mix up the surface and put out the side of the sheet that is covered with a protective film.

All manufacturers of cellular polycarbonate, both Russian and foreign, which value their reputation, pay great attention to protecting their products from ultraviolet rays. And companies from China do not think about it at all, so it is not surprising that the materials produced by them are released without any protection or it is, but purely symbolic.

The protective film as such on the surface of the material Chinese manufacturers do not apply. They are limited to simple addition in the production of polycarbonate special additives that provide some protection from solar radiation. This leads to the fact that the greenhouse, built of Chinese polycarbonate, serves no more than 3 years. After this time, the material becomes muddy, and then begins the process of its destruction.

Therefore, in order for the construction on your site to serve for a long time, it is necessary to immediately purchase expensive and high-quality material from a reputable manufacturer. The choice made in favor of the products of an unknown Chinese company will ultimately save money, but then you regret it, because after a couple of years the greenhouse will have to be redone. If you purchased high-quality polycarbonate, you can count on its service life of at least 10 years. During this time, poor quality material will have to be changed at least three times.

Polycarbonate Light - what is it?

Pursuing the search for polycarbonate, many gardeners pay attention primarily to the price. This is understandable, since the cost in relation to many products is the main indicator of its quality characteristics. However, a number of polycarbonate manufacturers go to the trick and offer budget material at the price of the standard.

Pursuing the search for polycarbonate, many gardeners pay attention primarily to the price. This is understandable, since the cost in relation to many products is the main indicator of its quality characteristics. However, a number of polycarbonate manufacturers go to the trick and offer budget material at the price of the standard.

This material is labeled Light and is of lower quality. Therefore, having seen a material in one of the firms that has such a label, you should know that instead of 4 mm you will get polycarbonate, whose thickness parameter will be 3.5 mm, and 6 mm thickness will be 5.5 mm. It should be understood that reducing the thickness of the material shortens its service life, so such a purchase cannot be considered advantageous.

Manufacturer selection

Making a choice in favor of polycarbonate for the winter greenhouse, most of the summer residents want to choose a product with an excellent price-quality ratio. In this regard, it will be quite logical to indicate major brandscurrently offered on the market, and their quality characteristics.

-

The producer known in the Russian market - the Carboglass company offers qualitative polycarbonate on which the company gives a guarantee not less than 15 years. The products of this manufacturer belongs to the group of quality. The price of these products is an obvious proof of this. If you decide to purchase Carboglass polycarbonate with a thickness of 6 mm and a sheet size of 2.1 x 6 m, it will cost you 6000 p.

The producer known in the Russian market - the Carboglass company offers qualitative polycarbonate on which the company gives a guarantee not less than 15 years. The products of this manufacturer belongs to the group of quality. The price of these products is an obvious proof of this. If you decide to purchase Carboglass polycarbonate with a thickness of 6 mm and a sheet size of 2.1 x 6 m, it will cost you 6000 p. - Another Russian manufacturer - the company Novattro. She offers high quality products and gives a guarantee of 14 years. The cost of the material is 4600 p. for one sheet 6 mm thick.

- Another company specializing in the production of polycarbonate is Plastilux concern. She manufactures products under the brand Sunnex. It offers fairly high quality polycarbonate with a durability of 8 years. The cost of one sheet with a thickness of 6 mm is 5000 p.

- Another brand can be found on the Russian market - Vizor. Previously, it belonged to manufacturers from China. She recently changed her residence permit, and now its production is in the Czech Republic. The quality of the product from this manufacturer is rather mediocre. On polycarbonate, this manufacturer gives a guarantee of 5 years. A price tag on a sheet of polycarbonate is 2700 p.

- Inexpensive polycarbonate releases another Chinese brand - ITALON. 2400 rubles - so much is a sheet with a thickness of 6 mm. However, it will not last long, since the manufacturer claims a guarantee not exceeding five years.

It is only major manufacturerswhich are presented in the Russian market. When choosing a product, the main characteristic that is worth paying attention to is durability and reliable protection against ultraviolet rays.

Conclusion

Many summer residents for the cultivation of horticultural crops outside the warm season use greenhouses. Previously, the device used glass. Now applied modern material - polycarbonate. However, choosing it is not so easy, since the market offers fair share of substandard products. Therefore, it is necessary to know which polycarbonate is best for the greenhouse. To create a greenhouse served for a long time, it is necessary to give preference to quality material of sufficient thickness. You should choose the products of well-known companies, then your greenhouse will not require attention to itself for the next ten years.