For the protection of the suburban area there is a wide choice of fences made of concrete, plastic, metal profile, chain-link mesh, etc. Some of them shade both their own and the neighboring section, and this prevents normal growth of plants. Various pests also appear in the shadows. This fence destroys the soil and plantations. The latter type of fence does not occupy the first place in the list, but it is still quite in demand among many summer residents.

For the protection of the suburban area there is a wide choice of fences made of concrete, plastic, metal profile, chain-link mesh, etc. Some of them shade both their own and the neighboring section, and this prevents normal growth of plants. Various pests also appear in the shadows. This fence destroys the soil and plantations. The latter type of fence does not occupy the first place in the list, but it is still quite in demand among many summer residents.

An excellent option for giving is the fence of the grid-chain-link. He is metal steel wire. Wire spirals twisted one to one.

Content

- 1 Chain-linkage: advantages and disadvantages

- 2 Methods for the manufacture of mesh-chain-link

- 3 How to choose a netting net

- 4 How to make a fence of the netting chain with their own hands

- 4.1 We stretch the mesh chain-link

- 4.2 Install the mesh section of the chain-link

- 5 Reviews of mesh fences - chain-link

Chain-linkage: advantages and disadvantages

Any owner of the suburban area seeks to fence his land. And the fence should be and robust and durable and reliable.

Advantages of a fence from a grid chain-link:

-

low price;

low price; - installation does not require special skills, easy and simple;

- the site is sufficiently affected by the sun's rays;

- long service life;

- the appearance of the grid can be decorated with climbing plants;

- does not need care (painting, editing

etc. )

The disadvantages of the chain-link include:

- it is impossible to hide a plot from prying eyes (possibly in the case of decorating with weaving plants);

- there is no sound insulation;

- the netsinkovanny grid quickly rusts.

If you want to purchase an inexpensive but relatively quality material then for the fence of the dacha territory, the technical zone, the lake, the sports grounds, the chicken coop and the paddock, the chain-link net perfectly suits.

Methods for the manufacture of mesh-chain-link

For the manufacture of mesh used wire from low-carbon steel. It can be uncoated, galvanized or polymer coated. A special machine twists the spiral and automatically rolls into rolls. Nets are made by various technologies. The result is a non-galvanized, polymer coated or hot galvanized.

For the manufacture of mesh used wire from low-carbon steel. It can be uncoated, galvanized or polymer coated. A special machine twists the spiral and automatically rolls into rolls. Nets are made by various technologies. The result is a non-galvanized, polymer coated or hot galvanized.

Non-galvanized mesh is produced from ferrous metal. If it is not painted immediately after installation, it will start to rust. In order to have a beautiful and well-groomed appearance of the grid, it must be repainted every 3 years.

Galvanized mesh is most sought after by consumers because does not corrode maintains various temperature conditions. It is made in two ways: electrolytic,

Polymer coated mesh is the most convenient and practical. And its price is correspondingly higher. The mesh is covered with polymeric materials (polyvinyl chloride or PVC coating), which also protects against negative influences and have an aesthetic appearance. The size of the cells may be different: 10 × 10 or 65 × 65. The ends of the mesh are curved and twisted.

There are 2 types of a fence from a grid of the chain-link - tension and section. The first type is the cheapest. It is not difficult to assemble the tension grid of the chain-link: it is mounted on a pole, unwound to another pole, then tensioned and attached to the pole. In this case, the pillar may be wood, metal or concrete.

The cost of the sectional fence is much higher stretch. This type of fence has a frame section in which the grid is installed.

How to choose a netting net

-

Low cost netting-nets (non-galvanized) after installation should be covered with special protective agentso that the net does not rust from moisture.

Low cost netting-nets (non-galvanized) after installation should be covered with special protective agentso that the net does not rust from moisture. - If you chose a grid with a polymer coating, you need to pay attention to its quality. If in the inside there are scratchesthen this is substandard material.

- Make sure that when you click on the edges of the chain-link, they do not diverge.

- Долговечность и надежность сетки зависит от величины и диаметра ячеек и проволоки. Некоторые производители размеры ячеек увеличивают, а толщину проволоки уменьшают. При этом масса сетки может отличаться по ГОСТ. Если различие в массе достигает 5%then this is substandard material.

The mesh is rolled into rolls and sold as such in a store. The height reaches 1.5 m, the length is 10 m. If a size larger than the standard is required, then the necessary length and height of the chain-link can be ordered.

How to make a fence from the netting chain with their own hands

First you need measure the plot. To drive the pillars into the ground every 2.5−3 m. The required number of pillars is considered as follows: the size of each side of the plot divide by 2.5. For example, you have a plot of 32 m. So 32 / 2.5 will be 12.8. The integer turns out very rarely, so in this case, we must take 13 pillars and set at a distance of 2.46 meters from each other, or take 12 pillars and set each one at a distance 2.5 meters. Only the distance between the last pillars make a little less. The first method is not the best, because you can not accurately calculate 2.46 meters, the second more acceptable.

First you need measure the plot. To drive the pillars into the ground every 2.5−3 m. The required number of pillars is considered as follows: the size of each side of the plot divide by 2.5. For example, you have a plot of 32 m. So 32 / 2.5 will be 12.8. The integer turns out very rarely, so in this case, we must take 13 pillars and set at a distance of 2.46 meters from each other, or take 12 pillars and set each one at a distance 2.5 meters. Only the distance between the last pillars make a little less. The first method is not the best, because you can not accurately calculate 2.46 meters, the second more acceptable.

To determine the height of the corner and intermediate pillars, it is necessary to the width of the chain-link add 10 cm and for poles about 1- 1.5 m. A large load falls on the corner pillars, therefore it is better to drive the pillars into the ground by 20 cm First, you should install the corner posts, and then only intermediate.

Further base is needed pour cement. You can dig deep holes, fill a small layer of sand there. Then install the pillars and fill it with rubble or shards of brick. Base again fall asleep with sand and fill with water. Pour this layer with cement mortar. The quantitative ratio of cement, sand and water is 1: 4. Monitor the location of the pillars, they must be smooth. To do this, pull the thread and check it. The grid is installed when the concrete is completely hardened.

We stretch the mesh chain-link

To stretch the mesh, you first need weld hooks on the support. These can be nails, screws or any other available materials. In the next step, we stretch the chain-links on the posts. Straighten the roll and set about the first pillar. To fix the grid you need it hang on hooks. Next, we pass a thick wire vertically into the first row of the grid. The cross section of the grid should be 4 mm. Grid hang on the hooks, and the cable or wire weld to the post. This is necessary so that the grid does not subside and does not bend.

To stretch the mesh, you first need weld hooks on the support. These can be nails, screws or any other available materials. In the next step, we stretch the chain-links on the posts. Straighten the roll and set about the first pillar. To fix the grid you need it hang on hooks. Next, we pass a thick wire vertically into the first row of the grid. The cross section of the grid should be 4 mm. Grid hang on the hooks, and the cable or wire weld to the post. This is necessary so that the grid does not subside and does not bend.

Next, roll the mesh reel to the next post, thread rod or wire in the first cells and tighten the grid. Assembling the grid to one is not easy, the grid can not be pulled very well, it is better when there is an assistant.

After that, horizontally thread the cable and weld to the post. From the top and bottom edges, the distance should be 10-20 cm The grid on the other pillars is installed in the same way. It may turn out that there will be 1.5 meters, and you need to tighten 2.5. To do this, take new canvas attach to the remainder one to one and weave in between wire. Ultimately, you get a solid mesh.

After stretching the mesh of the entire area, bend the hooks.

The last stage of the arrangement of the grid-chain-link is its painting. Speakers antennae for safety needs to be twisted.

Set the mesh section of the chain-link

If you purchased a sectional mesh, then it is installed in the following way. First you need weld frame for the section. For this you need a corner of 30 × 4 or 40 × 5 mm. Take away 15 cm from the distance of two pillars - this is the length of the frame. Next, take away from the height of the pillars 10 cm - is the width of the frame. After all measurements, weld the corners.

If you purchased a sectional mesh, then it is installed in the following way. First you need weld frame for the section. For this you need a corner of 30 × 4 or 40 × 5 mm. Take away 15 cm from the distance of two pillars - this is the length of the frame. Next, take away from the height of the pillars 10 cm - is the width of the frame. After all measurements, weld the corners.

Mesh roll reduce if necessary to the desired size. It is necessary to fix a grid as well as tension. Rods pass through the upper and lower rows of the grid, we stretch the grid and weld to horizontal corners. Ultimately, you should have a net, with rods or cables welded inside.

To the existing posts in a horizontal position to weld metal strips, the length of which should be 20−30 cm, width - 5 cm, and a section of 5 mm. Set the resulting section between the pillars and weld to the strips.

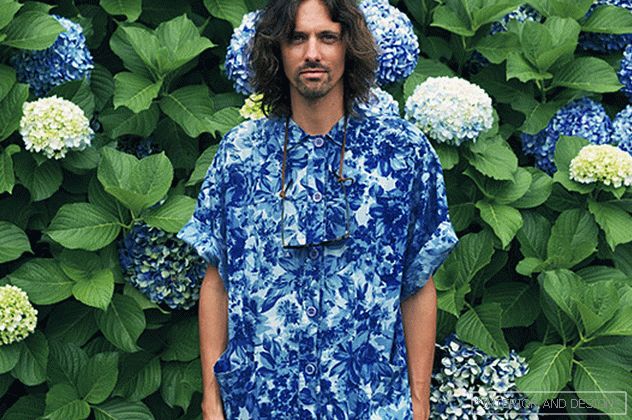

Fence из сетки — рабицы easy to do 2–3 people are required for assistance

Reviews of mesh fences - chain-link

I think the fence of the netting is the perfect solution as for country, and city houses. Price pleasantly surprised. The only negative - the neighbors are all in sight. But this is not a problem, as now there is a huge selection of woven plants. It is not expensive, and you can install it yourself.

Oleg, OmskThe netting is very practical to use. But as for the quality of the material, it leaves want something better When bought in rolls, part of the grid was defective (curved threads). You will not bring back and you will not prove anything. Therefore, I advise you to take immediately from the warehouse.

Alexey, NovgorodTwo years ago, put the galvanized plastic. Very high quality does not rust, does not react to temperature drops. Very satisfied, and I advise everyone.

Vladimir, Moscow