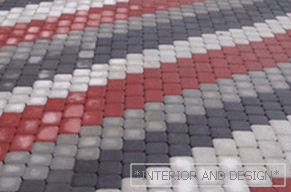

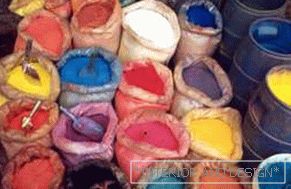

Dyes for paving slabs are powdered materials that allow concrete to be painted in different colors. Coloring is carried out by mixing the powder with a viscous liquid such as a concrete mix. These dyes are obtained by grinding materials of different origin, both natural and artificial.

Dyes for paving slabs are powdered materials that allow concrete to be painted in different colors. Coloring is carried out by mixing the powder with a viscous liquid such as a concrete mix. These dyes are obtained by grinding materials of different origin, both natural and artificial.

Content

- 1 Requirements for dyes for paving slabs

- 2 Types of dyes and methods for their preparation

- 3 The choice of dye for paving slabs

- 4 The cost of pigments for paving slabs

Requirements for dyes for paving slabs

Pigments that paint paving slabs must meet the following requirements:

- not allowed them solubility in water;

- pigments do not react with cement;

- not pale from ultraviolet rays, external physical effects and various natural phenomena;

- tile paint should to withstand the aggressive environment, which she creates cement strongly alkaline substances.

The main properties that must have any quality pigments for paving slabs:

-

Светостойкость - the paint should not discolor from external exposure to sunlight;

Светостойкость - the paint should not discolor from external exposure to sunlight; - High coloring ability - the pigment should transfer its color to the stone without any distortion;

- Resilience to various chemicals that may reach the surface of the tile at different times of the year;

- Heat resistance is an important factor, as there are often sharp changes in air temperature;

- Corrosion Resistance and external mechanical effects of different types and levels of load.

Types of dyes and methods for their production

In general, dyes for pavement tiles can be divided into three types:

- Synthetic dyes have a complex chemical composition. They are obtained through chemical reactions of high complexity and various technological processes that require maximum precision.

- Metallic pigments - These are alloys of aluminum, copper, zinc, bronze and other non-ferrous metals. As a result, the resulting dye is a metal powder.

- Natural (natural) dyes are obtained from minerals and rocks through high temperature processing, grinding and enrichment.

The most popular at the moment are inorganic, that is synthetic dyes. This group includes the most pigments, in addition, their performance is very high quality.

The most popular at the moment are inorganic, that is synthetic dyes. This group includes the most pigments, in addition, their performance is very high quality.

From the dye and its dosage may directly depend the quality of the tile itself. It is very important to take into account the time of forcing pigment into the mixer and the method of mixing components. It is important to follow the complete pattern of action, from creating a concrete mix to its final curing, which already has a certain color.

The choice of dye for paving slabs

What can affect the choice of pigment for the tile, which factors the most important:

- type of production;

- type of cement;

- type of coloring pigment;

- the reasonableness of the cost of creating this line of sales;

- average cost from a particular manufacturer.

The cost of pigments for paving slabs

On average, pigment can cost from 50 to 150 rubles for 1 kg, and the exact price depends on various factors:

On average, pigment can cost from 50 to 150 rubles for 1 kg, and the exact price depends on various factors:

- manufacturer and supplier;

- the name of the pigment;

- type of dye.

The cheapest is black paint, scarlet shades are a bit more expensive, and the most expensive is green. Usually pigments are sold in packs of 20 or 25 kg.

Many people prefer to buy exactly painted pavement tiles, as it is able to cheer up and brighten up everyday life, unlike simple gray pavements. After all, it is always more pleasant to see colorful colors than not to notice around anything but dullness.