The coatings industry has gone far ahead. There was a lot of new building and finishing materials. But many of them can hardly be called environmentally friendly.

Moreover, some of them generally have a very definite service life, and then simply fall apart with all the ensuing consequences. A floorboard, by definition, is environmentally friendly for one hundred percent. Moreover, its dimensions can vary widely.

Половая доска – размеры, характеристики, свойства--> Половая доска – размеры, характеристики, свойства

Половая доска – размеры, характеристики, свойства

Even in a strict, minimalist style of hi-tech, the floor of natural flooring fits perfectly. And for rooms in the style of country - it's just a mandatory attribute.

The benefits of flooring have long been known. This naturalness, good thermal insulation properties, tactile sensations, noise insulation, ease of use and beautiful appearance.

Of course, there are disadvantages. These include: demanding care, a tendency to abrasion, a possible change in geometry under the influence of moisture and temperature changes.

How to choose a floorboard correctly

The choice of wooden boards for flooring is reduced to ensure that it does not spoil the aesthetic appearance of the room and fulfilled its purpose during the planned period.

Which board is better to use for the floor - the factors of choice

1. Wood species and wood structure

The market has a large selection of lumber from both domestic (for example, Arkhangelsk, Kirov, Kostroma) and foreign manufacturers, offering a board of different varieties and species.

Of course, speaking of wood, the first thing that comes to mind is the drawing, the structure of the tree. All breeds have their own unique pattern. However, the rock also affects the strength, the possible thickness of the material and the duration of operation.

Floorboard - photo examples of wood species

Floorboard pine, spruce--> Floorboard pine, spruceFloorboard pine, spruce

Floorboard pine, spruceFloorboard pine, spruce

Larch floorboard--> Larch floorboardLarch floorboard

Larch floorboardLarch floorboard

Maple flooring--> Maple flooringДоска пола из клёна

Maple flooringДоска пола из клёна

Oak flooring--> Oak flooringПоловая доска дуб

Oak flooringПоловая доска дуб

Birch flooring--> Birch flooringДоска пола береза

Birch flooringДоска пола береза

Cherry flooring--> Cherry flooringДоска пола из вишни

Cherry flooringДоска пола из вишни

2. Density of wood species

Deciduous species: beech, maple, oak have a high density of wood, conifers: larch, pine, spruce - less dense. At the same time, the latter are more popular. This is due to the fact that wood with a lower density, lighter, makes less demands on fasteners (screws, hardware, nails).

If you plan to install the floorboard with your own hands, then working with pine is much easier. And most importantly - conifer wood is cheaper.

3. Dimensions of the floorboard

Dimensions, technical parameters:

Floorboard thickness

Along with the density of wood, the thickness of the floorboard is another indicator that characterizes the possible duration of use. On the market there are boards with a thickness of 20-70 mm.

How thick should the floorboard be?

Depends on the pitch lag under the floorboard, if the distance between the lags for the floor is 60 cm, then a thickness of 30-35 mm is sufficient, if more than 60 cm, for example, 80, then it is optimal to use a board 40-45 mm thick. It will be correct to include in the calculation the intensity of movement in the room, the higher it is, the thicker the board should be.

For the living room is used board 35-40 mm thick. For rooms with high loads, for example, hall, living room or in commercial premises, gyms, the thickness of the board should be higher. When choosing a thickness, it is important to achieve an optimal price / thickness ratio. After all, the thicker the board, so it is more expensive.

Floorboard width

The floor board is 80-135 (140) mm wide. This indicator determines the number of longitudinal joints. The smaller they are, the easier it is to mount the plank floor and sustain the geometry of the board. At the same time, laying a wide board is more difficult work (subjective opinion, because it depends on the carpenter and the quality of the lumber, in particular, its moisture and geometry are important).

Plus, it should be noted that the proportions of the board (width-thickness) directly affect the stability of the flooring, since wide floorboards are more susceptible to warping (due to humidity drops).

In private construction, boards with a width of 100-105 mm and thickness of 30-36 mm gained the most popularity.

Floorboard length

There are sizes from 3,000 to 6,000 mm. Choose the length based on two requirements - a minimum of joints and a minimum of waste.

Unlike the usual, Eurodoska comes in sizes 2-3-4-6 meters. Due to this, it is possible to reduce waste for trimming, choosing the desired length.

4. Types of flooring and manufacturing methods

Board floor can be made in two versions: solid board and spliced (glued). The first is made from solid wood. The second is from spliced (glued) pieces. And each of the options has its advantages.

It is also divided into tongue-and-groove (has protrusions - grooves, thorn-groove) and non-grooved.

There is a conventional board and eurodoske for the floor (special production technology, equipment and quality of raw materials). The latter is more expensive, but it has indisputable advantages (low humidity, ideal geometry, no defects (blue, holes, cores and rotten knots), smooth surface, the pile does not rise in the process of varnishing).

Massive board on the floor pros and cons

Massive flooring--> Massive flooring

Massive flooring

Benefits: natural wood;

disadvantages: possible knots, resin pockets, which reduce the quality of the board.

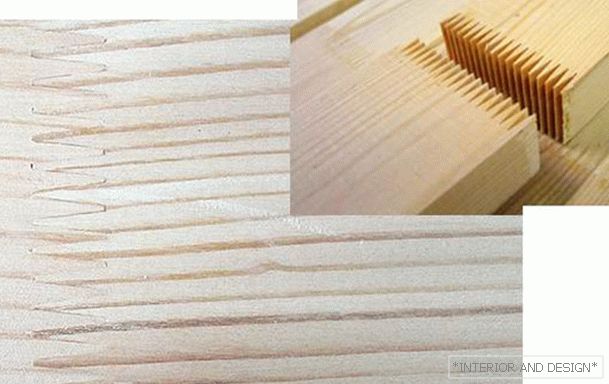

note. High-quality massive euroboard (Europol) has ventilation slots (the same as in the European racing). They allow you to save wood longer. Prevent the development of fungi. In addition, they allow to distribute the load on the board and prevent the wood from warping.

Floorboard with ventilation slots--> Floorboard with ventilation slots

Floorboard with ventilation slots

Spliced flooring board плюсы и минусы

Benefits:

- high strength;

- no knots;

- perfect geometry.

disadvantages:

- the presence of adhesive composition;

- increased lagging requirements (400 mm installation pitch).

5. Surface quality

The evenness of lag, planks and subfloor geometry is ideal - a guarantee that the plank floor will be laid without problems

Knots, giving the natural beauty of the board, should sit tight.

6. Humidity of a floorboard

The permissible moisture level is not more than 12-14%. Otherwise, the board will not last long.

No matter how good the wood, but with its features have to be considered. The fact is that different breeds have different coefficients of linear expansion from moisture. Moreover, in two directions - longitudinal and transverse, they also differ from each other. In the longitudinal direction, this coefficient is much larger. The smallest coefficient of expansion falls on the oak, followed by ash and tick.

Different types of wood differ in the percentage of their own resins, oils and tannins. The more of them, the less wood is subject to deformation from moisture. Therefore, wood is harvested in the cold season (autumn-winter), when the movement of tree sap is suspended.

Council When purchasing a board, it is better to independently check the moisture of the board using a moisture meter for wood. Also, you should not hope that it will dry out by the time it will have to be laid (rather, it will twist by that moment).

With improper "artisanal" drying, the board may lead, and there will be no one to make a complaint. Therefore, immediately buy high-quality sawn timber, the last chamber drying.

7. Packing floorboards

Regular board is supplied in plastic packaging, and Europol (Euro-board) in shrink film. Packing in PVC shrink film eliminates the ingress of air between the film and the board and as a result, the lumber does not absorb moisture during storage (provided good ventilation).

What is the difference between these types of packaging in practice?

Day and night there is a temperature drop, i.e. the boards heat up during the day and cool at night, causing condensate to collect on the film, which is absorbed by the wood. This happens with regular polyethylene packaging. A shrink film eliminates (eliminates) this effect and condensate can appear only on the outside (outside the package).

8. The cost of flooring

Coniferous wood is more common and affordable, and also simple in industrial processing. Therefore, the lower price of pine and spruce is a significant argument in favor of the purchase.

How do sellers consider flooring?

When selling flooring, the volume can be considered (unit) as cubes (cubic meters) or in m2 (square meters). Here you need to be careful, because there are not very decent sellers who, besides that, they consider the dirty (total) area of the board, i.e. taking into account the thorn-groove, it is also rounded off (arranged as a blank). As a result, the lumber is not enough to lay the estimated area.

For example, the working area of the board (width-length) is 36x135, with grooves 37x141 mm, and if it is still counted as a blank (when released with cubic meters), it will be 41x149 mm. Multiply the value of two values (clean-dirty volume) and see what the difference in the amount will be.

8. Floorboard in the interior

Wood is a material that is well processed. Its structure can be artificially aged, or vice versa, to emphasize the clarity of the lines (impregnations, stain). The floorboard allows you to put a plank flooring with your own hands, which will create a unique atmosphere in your home and organically fit into any of the styles of interior design.

Floorboard in the interior of a wooden house--> Floorboard in the interior of a wooden house Flooring in the interior of a large living room with fireplace-->

Floorboard in the interior of a wooden house Flooring in the interior of a large living room with fireplace--> Flooring in the interior of a large living room with fireplace

Flooring in the interior of a large living room with fireplace

Tips for laying flooring - do it yourself installation

For a tight connection of boards used longitudinal grooves and protrusions (dowels), running along the entire side surface.

They are of two types: rectangular and trapezoidal. The latter is more practical, and therefore preferable to use.

Connect the floorboard tongue and groove--> Connect the floorboard tongue and groove

Connect the floorboard tongue and groove The technology of laying flooring involves the observance of a number of rules, the implementation of which guarantees the quality and long service life of the plank floor.

Rule one - the microclimate

The room and the board must be dry, especially during the installation process. Humidity boards should not exceed 14%, and the air in the room 60%. Before laying the board adapts to the temperature and humidity of the room, that is, should just lie in it for at least 3 days. For the same reason, waterproofing is required between the wooden floor and the concrete base.

Rule two - the sequence

Laying the board on the floor is last. Before this, the walls and the floor must be completely aligned.

Rule Three - competent laying of the floorboard

Boards are stacked on wooden logs or waterproof plywood. Screws are used for fastening.

The location of the boards should be from the front door along, and the lag, respectively, across. Lags must be aligned in height, otherwise the boards will protrude, which is unacceptable.

Boards are attached to logs with screws, passing from the side surface of the board at an angle. A through hole is drilled for them.

With the help of two clamps and wooden sticks, which prevent damage to the surface, the adjacent boards are preliminary attracted to each other in order to prevent the formation of cracks.

Fixing the floorboard with screws and screed clamps--> Fixing the floorboard with screws and screed clamps Laying the floorboard on the floor-->

Fixing the floorboard with screws and screed clamps Laying the floorboard on the floor--> Laying the floorboard on the floor

Laying the floorboard on the floor

Between the wall and the floor in both directions there is a gap of about 5 mm in the transverse and 7-8 mm in the longitudinal direction of the boards on each side. This is done on the basis of those considerations that in case of wetting in an emergency, the board will begin to swell, and if there is no gap, the floor will simply swell up.

The fourth rule is processing.

After laying the floor to be processed. To do this, you can simply paint it, but rather varnish it. Pre-boards are saturated with linseed oil. On this device the floor of the board ends. It remains only to put a plinth at the edges.

Conclusion

Now you know exactly what to look for when choosing a floorboard, as well as in what dimensions (dimensions) it is produced and what parameters it has. Using this knowledge, you will be able to choose the right lumber, and the floor laid out of it will last at least 40-50 years. At the same time, it will be warm, beautiful and environmentally friendly.