Sliding gates на сегодняшний день нашли свое очень широкое применение. Их используют как для дома и гаража, так и для офиса. Sliding gates, или их еще называют откатные, хорошо зарекомендовали себя там, где имеется плотная застройка. Это связано, прежде всего с тем, что при их открывании требуется определенное количество места.

Sliding gates на сегодняшний день нашли свое очень широкое применение. Их используют как для дома и гаража, так и для офиса. Sliding gates, или их еще называют откатные, хорошо зарекомендовали себя там, где имеется плотная застройка. Это связано, прежде всего с тем, что при их открывании требуется определенное количество места.

Content

- 1 The essence of the sliding gate and their features

- 2 pros и minuses раздвижных ворот

- 3 Building a sliding gate

- 3.1 Necessary tools for creating sliding gates

- 3.2 Basic rules for the manufacture of sliding gates do it yourself

- 3.3 Phased manufacturing of sliding gates

- 4 Sliding Gate Cost

The essence of the sliding gate and their features

Sliding gates — это своеобразное ограждение и в то же время дверь, которая открывается в автоматическом режиме.

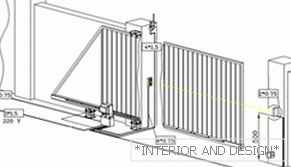

The most popular cantilever sliding gates, as they occupy a minimum of space. They, depending on the preferences of the owner, can open either to the right or to the left.

The most popular cantilever sliding gates, as they occupy a minimum of space. They, depending on the preferences of the owner, can open either to the right or to the left.

The use of automatic systems in combination with this type of gate greatly improves the convenience of their operation. For even greater convenience, such gates are equipped with a wicket, thanks to which the sliding gates will not need to be opened every time a person wants to enter.

pros и minuses раздвижных ворот

Sliding gates, как и все конструкции, имеют свои положительные и отрицательные стороны.

pros sliding gates:

- Elevated safety guarantee. Such “doors” are much harder to open.

- It has excellent bearing capacity, and they are also very durable.

- Such designs are quite safe. at the entrance and exit cars.

- Are great time saving in winter. Opening and closing of such gates does not require clearing large amounts of snow.

In addition to the advantages, sliding gates have minuses:

-

There is no wicket in the sliding gate. Although it can be embedded, but it is quite time-consuming process.

There is no wicket in the sliding gate. Although it can be embedded, but it is quite time-consuming process. - It is difficult to find the necessary grating for direction. You can, of course, buy them in specialized stores, but for this you need to make a special calculation of the weight of the structure.

- Sliding gates значительно reduce space at the fence.

Despite these shortcomings, they can be compensated for, but this will require manpower and resources.

We build sliding gates

Necessary tools for creating sliding gates

For the manufacture of sliding doors with their own hands will need the following tools and fixtures:

- Welding machine 200 A. It is desirable semiautomatic, as it is convenient for them to weld both thick metal and sheet metal, thin. This does not form slag, and the quality of the weld is visible to the naked eye.

- Angle Grinder (angle grinder) or "grinder"as it is called in the people. "Bulgarian" it is desirable to use a small cutting disc with a diameter of 120 mm. According to the experience of many mechanics, using a larger grinder is harder and more uncomfortable.

- Would be useful electric drill 750 - 850 W with a set of drills for metal.

- Combination nut set keys.

- «Mounting"Or mount, and preferably two.

The basic rules for the manufacture of sliding gates do it yourself

For the manufacture of sliding gates, first of all, you need to have quite extensive knowledge in the field of technology, as well as the skills of fitter-installer and welder. In addition, you must be able to make at least simple sketches and diagrams.

The manufacture of the gate begins with drawing design or sketch. In the drawing, you must specify all the elements and dimensions of the future design. Next, specify the technical conditions. Desirable to produce strength calculation. The drawing needs to develop a specification - a list and quantity of the necessary materials and components or components. Next, you need to develop a manufacturing process - work plan step by step, which will need to carry out the installation of the gate.

The manufacture of the gate begins with drawing design or sketch. In the drawing, you must specify all the elements and dimensions of the future design. Next, specify the technical conditions. Desirable to produce strength calculation. The drawing needs to develop a specification - a list and quantity of the necessary materials and components or components. Next, you need to develop a manufacturing process - work plan step by step, which will need to carry out the installation of the gate.

According to the specification to purchase the necessary materials, components and tools.

It is necessary to plan the manufacture of sliding gates simultaneously with the planning of the fence, where these gates will be installed, since the supporting structures (pillars) will be the basis for both the fence and the gate. Therefore, when planning a sliding gate, it is necessary to lay in advance the design reinforced bearing parts.

The posts can be made of steel pipe, channel and other products with the possibility of welding the gate construction elements to them. Pillars needed concrete.

The width of the opening of the sliding gate should be within 3−3.5 m and should allow passing trucks. If this is not required and is not planned in the future, then the width of the opening is of such a size that a planned transport can pass without difficulty. The margin over the width of the door opening must be between 30-35 cm on each side.

Make desirable single gateas it will facilitate the manufacture and installation of the structure. However, such gates are stronger and more reliable.

Make desirable single gateas it will facilitate the manufacture and installation of the structure. However, such gates are stronger and more reliable.

In the manufacture of sliding gates it must be borne in mind that with the width of the gate itself, for example, 3 m, the fence or fence of the side where the gate will move should be at least 2 times longer. This condition must be observed precisely for the designs of sliding gates. Most suitable height gate - 2 -2.5 m, but if necessary it is possible and more, since it is not critical. The height depends on the height of the fence or fence.

Phased manufacturing of sliding gates

- With the help of the "grinder", the sections of the profile pipe of the required dimensions of the gate dimensions are cut off. It is desirable to cut at an angle of 45º. It should be noted that it is desirable to perform cutting work on a special cutting machine for metal, with the ability to adjust the cutting angle. The quality of such a cut is noticeable, which subsequently will affect welding.

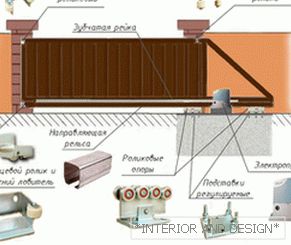

- Pipe welding "Butt". When welding, you need to set the pipe sections at an angle of 90º, as well as control the diagonals. This is one of the most important conditions. Further quality and ease of manufacture depend on this. Everything must be done strictly "in the corner." In case a defect is found after welding, it is necessary to redo it. After welding, you should get a frame with a length of 6 m, provided that the gate opening is 3 m, that is, the frame is made 2 times more than the opening. Inside the frame of the same pipe are welded diagonally for structural rigidity. For the manufacture of applied profile tube estimated dimensions. For example, in most cases a square tube with dimensions 50 × 50 × 4 will be suitable for standard gates.

- Further along the length of the fence to the posts at the height of the upper edge of the gate is welded channel groove down. In the lower part of the fence is welded the same channel groove up. The gates themselves will be inserted into these slots. The channel from No. 6 to No. 10 is usually applied.

-

The channels are made holes for mounting the guide and power rollers. In other cases, it is necessary to weld the corresponding brackets, according to the design according to the drawing. In any case, the rollers should be like lateral and vertical. It is enough to install 3 rollers on each side of the channel: one on each side and one in the middle. Clips should be purchased complete with axles and brackets. Commercially available rollers of various diameters. It is advisable to purchase rubberized rollers, since during operation of the gate, the noise of opening and closing the gate will be significantly reduced.

The channels are made holes for mounting the guide and power rollers. In other cases, it is necessary to weld the corresponding brackets, according to the design according to the drawing. In any case, the rollers should be like lateral and vertical. It is enough to install 3 rollers on each side of the channel: one on each side and one in the middle. Clips should be purchased complete with axles and brackets. Commercially available rollers of various diameters. It is advisable to purchase rubberized rollers, since during operation of the gate, the noise of opening and closing the gate will be significantly reduced. - In the grooves of channels set manufactured gate frame, which moves on the established rollers. The rollers must be attached with the possibility of regulation, that is, eccentric, so that you can adjust the gap, excluding the clamping of the gate.

- At the end of the opening on the opposite side is set limiting bracket посредством сварки или прикручивается, что более предпочтительно, так как есть возможность регулировки. Кронштейн изготавливается из куска channelа по всей высоте ограждения. Ворота при закрытии входят в паз этого channelа, образуя надежное закрытие. В нижней части этого же channelа устанавливается удерживающий силовой ролик. Для поддержания ворот и разгрузки конструкции от так называемого усталостного прогибания.

- Front and back doors welded sheets of metal 1.2–2 mm thick. Decorated with decorative forged or stamped elements.

- Welded or screwed handles for movement gate in the case of a manual drive. Staples, hinges or another mechanism are welded to close the gate from the inside.

For the manufacture of mechanical drive will need installation electromechanical gearmotor power about 2 kW. For this purpose, a steel sprocket is attached to the gate by means of welding, onto which the chain extends through the drive sprocket of the gearmotor motor, which in turn is mounted on a bracket at the furthest point of the gate construction, from the side of gate opening.

An asterisk on the gate is welded on the end of the side facing the gearmotor. The motor-reducer can be both single-phase for 220 V and three-phase - 380 V. If you have electrician skills, you can install a capacitor on a three-phase motor to run into a single-phase network.

At installation of the electromechanical drive it is necessary to provide limit switch which is installed in one of the places where the shutdown will occur when the gate is fully closed. The limit switch can be both electromechanical and electronic (optical). Drive control is displayed on the remote control by cable brand

Sliding Gate Cost

The cost of a complete set of sliding gates will be approximately the same, although the final price will depend on the type of mechanism chosen, the equipment, and the material of manufacture. So, prices will vary within 25−40 thousand rubles.

And in the event that you still choose your own production and installation of sliding gates - they will cost you the sum no more than 15 thousand rubles.

Sliding gates — идеальное решение для Вашего загородного участка. Они обезопасят и в то же время украсят его. Сделав же их своими руками, Вы значительно сэкономите средства.