In most cases, when arranging the territory of a suburban area, it becomes necessary to build garden paths. Their main task is to connect the house with other buildings: bath, gazebo, swimming pool, outbuildings

In most cases, when arranging the territory of a suburban area, it becomes necessary to build garden paths. Their main task is to connect the house with other buildings: bath, gazebo, swimming pool, outbuildings

Garden paths are not at all difficult to do on your own. To do this, it is not at all necessary to be an experienced specialist in this field; it is enough to familiarize yourself with the main rules for carrying out the work and select the optimal building material.

Content

- 1 What are garden paths?

- 1.1 Paths

- 1.2 Bulk walkways

- 1.3 Jellied tracks

- 2 Garden paths from wood cuts and bars

- 3 Garden paths from paving slabs

- 4 technology of mixing concrete slabs for tracks

- 5 Natural stone paths

- 6 Paths from plastic modules

- 7 Video review of garden paths

What are garden paths?

Paths

Such paths arise without any additional effort on the part of a person: trampled down by feet, driven by car

Such paths arise without any additional effort on the part of a person: trampled down by feet, driven by car

In order for the path to become a good garden path, you should ensure diversion of standing water. It is very simple to do this - it is necessary to cut the mounds on the footpath and fill the pits, sprinkle it with sand (with the addition of rubble) and tamp it well. The edges of the walkway can be lined with cobbles or planted with low plants that hold the ground.

Bulk walkways

This type of garden paths is the most popular in the countryside. For their construction digging bed depth of about 10 centimeters, covered her bottom and sides with a thick film or geotextile and covered with rubble, gravel or pebbles to the level of the soil. You can give a walkway a beautiful appearance by laying stones, cobblestones, paving tiles on it in some places.

Jellied tracks

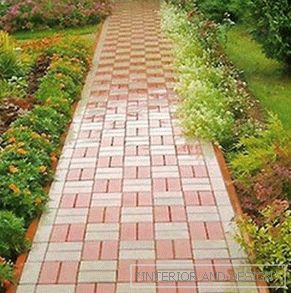

Such garden paths most practical and able to withstand heavy loads. Paving slabs, cobblestones, paving stones, sandstone can serve as a material for covering such paths.

Such garden paths most practical and able to withstand heavy loads. Paving slabs, cobblestones, paving stones, sandstone can serve as a material for covering such paths.

Quite often these tracks do a bit. towering above ground levelto ensure rainwater runoff and reduce surface contamination by dust and dirt.

Garden paths from wood cuts and bars

Paths from a tree are excellent option for registration of the territory of a garden site. This available material allows you to not only save your money, but also naturally fit into any style of landscape design. Today, for the construction of garden paths made of wood most often use the bars and cuts.

For the construction of tracks from the bars it is recommended to use materials made of hard wood. Bars are cut into identical elements with a length of 1 meter, a width of 30 centimeters and a height of 20 centimeters. After that, they are carefully treated with fuel oil or other composition to increase the moisture resistance of the material and protect against rotting. Bars are laid on a base of fine gravel, rubble or sand.

This work of art can be created if you use for device tracks wood cuts различных размеров, цветов и рисунков. Для этого даже не потребуется денежных вbedний — достаточно распилить на части одинаковой длины стволы и ветви поваленных деревьев.

Construction technology The tracks are as follows:

- выкапывают bed глубиной около 15 сантиметров;

- its bottom and walls are covered with geofabric;

- sand is poured on the bottom and tamped tightly;

- on the sandy cushion, the cuts are set (so as not to form voids, the large cuts alternate with the small ones) and sprinkle them to the top with screenings.

Garden paths from paving slabs

Today the paving slabs are the most widespread material for production of paths in the territory of garden sites. This is due to the high strength, durability and beautiful appearance of the material. Construction works are carried out in several stages:

-

Calculate the required number of tiles. For this, a drawing is made and the layout and form of the elements are selected. The path can be made from the same paving slabs, and by alternating products of various colors and shapes.

Calculate the required number of tiles. For this, a drawing is made and the layout and form of the elements are selected. The path can be made from the same paving slabs, and by alternating products of various colors and shapes. - Markup Execution Carried out using a measuring tape, pegs and lace (wire). To check the convenience of the laid track, it is recommended to walk along it after the end of the marking.

- Preparation of the base. На данном этапе, согласно выполненной разметке, выкапывают bed глубиной около 20 сантиметров. На дно насыпают щебень, накрывают его геотекстилем, присыпают слоем песка и утрамбовывают. Поверх песка насыпают сухую цементно-песчаную смесь слоем приблизительно 4 сантиметра и разравнивают ее.

- Laying paving slabs. Lay tile in the direction of "from itself". Each product should be tamped using a wooden mallet. Between the elements should remain a gap of 1-2 millimeters. First of all, the whole tile is laid, and then the products are cut into pieces of the desired size and the remaining spaces are filled. After completion of tile laying, the flatness of the track is checked at the construction level and, if necessary, corrected with a rubber hammer.

- Installation of the curb and sealing seams. Border spread on the edge of the track, fixing cement-sand mortar. At the very end of the work, the joints between the tiles are sealed up: a mixture of sand and cement is poured into them and watered with water. In places where the mixture has subsided, this procedure is repeated.

Technology of mixing concrete slabs for tracks

Еще один вариант для создания садовой дорожки, не требующий значительных денежных вbedний — concrete plateshand made. All that is needed to create such a plate is to make a mold and pour the prepared concrete solution into it. Already after 3-4 days, when the solution is set, you can start paving the tracks.

For the manufacture of forms for concrete slabs will need wooden beam with a cross section of 5 × 5 centimeters. The timber is cut into segments equal to the size of the future slab, that is, the width of the garden path. Next, cut the bars fastened with nails, paint the inner surface of the paint. It is better to immediately make 3-4 molds to speed up the process of manufacturing plates.

For the manufacture of forms for concrete slabs will need wooden beam with a cross section of 5 × 5 centimeters. The timber is cut into segments equal to the size of the future slab, that is, the width of the garden path. Next, cut the bars fastened with nails, paint the inner surface of the paint. It is better to immediately make 3-4 molds to speed up the process of manufacturing plates.

To prepare a concrete solution, we take cement, sand and gravel (crushed stone) in a ratio of 1: 2: 4, gradually add water and mix thoroughly. The finished solution should have a consistency in which it does not spread and crumble.

The finished form is placed on a flat surface covered with plastic wrap. In them, half the solution is poured, laid on top reinforcement and top up the solution. Then mortar tamped and level the surface with a trowel.

After the plate has hardened enough, with the help of the chisel we detach one side of the mold and carefully remove it. Next, the form is reattached and the process is repeated with a different plate.

For the device of the garden path of concrete slabs must first dig bed 10 centimeters deep and pour 5 centimeters on its bottom sand pillow. We lay the plates with a gap of no more than 3 centimeters and drive a mallet. At the last stage of work, the gaps are covered with sand and tamped.

Paths made of natural stone

Paths made of natural stone always looked very impressive. The material for their manufacture differs in strength, durability and beautiful appearance. The different shape, color and size of the stones allow you to create beautiful and unique garden paths.

Making the track begins with the calculation of the required number large stones by laying them along the future path. The basis for the track can serve as a sand pillow, poured into the bottom of the groove, dug to a depth of 5−10 centimeters. Sometimes it is necessary to process them to match the stones (for this you can use grinder).

Making the track begins with the calculation of the required number large stones by laying them along the future path. The basis for the track can serve as a sand pillow, poured into the bottom of the groove, dug to a depth of 5−10 centimeters. Sometimes it is necessary to process them to match the stones (for this you can use grinder).

Stitches between the stones can be filled with cement mixture or covered with sand. In the second case, the seams will soon overgrow with grass, which will give the path a more natural, natural look.

Paths from plastic modules

Plastic garden paths, despite the fact that they became popular not so long ago, quickly became widespread. It's connected with ease and speed of installation such elements. Finished plastic modules can be purchased inexpensively on the market or in a store - they can be both the same and different from each other in size and color.

In addition, plastic modules have excellent operational properties:

- long time save initial appearance and no wear;

- have holes for water flow;

- are odorless;

- do not rot;

- do not need special care, easy to clean and wash;

- do not collapse under the influence of precipitation and sunlight.

Plastic garden paths are laid according to the principle constructor. The basis for them can be almost any coating: sand, sod, clay

In addition to the above options for garden paths, you can use the most various materials: brick, parquet boards, rubber plates, plastic bottles and many others. It all depends on your imagination. But we should not forget that the material for the track should be safe during operation, and its appearance should be combined with the overall design of the site and buildings.