The main thing that determines the good performance of a chainsaw is proper and competent handling of the saw chain. With the wrong attitude to it, even the best model of chainsaw, purchased for a high price, will not be able to work as it should. The saw chain for the chainsaw must be properly used, tightened in time, honed as needed. The chain is the main element and one of the most important points is the correct choice of the necessary chain, since improper operation of the saw chain will lead to its breaking or stopping of work. Therefore, when choosing a chain, you should know with confidence: the chain pitch, profile, thickness of the leading link, the number of links and the purpose of the chain.

The main thing that determines the good performance of a chainsaw is proper and competent handling of the saw chain. With the wrong attitude to it, even the best model of chainsaw, purchased for a high price, will not be able to work as it should. The saw chain for the chainsaw must be properly used, tightened in time, honed as needed. The chain is the main element and one of the most important points is the correct choice of the necessary chain, since improper operation of the saw chain will lead to its breaking or stopping of work. Therefore, when choosing a chain, you should know with confidence: the chain pitch, profile, thickness of the leading link, the number of links and the purpose of the chain.

Content

- 1 chain selection

- 2 Chain sharpening for chainsaw

- 2.1 Sharpening frequency

- 2.2 File sharpening

- 2.3 Sharpening using a machine

- 2.4 Grinding with a grinder

- 3 Video sharpen chain chainsaw

Chain selection

On non-professional domestic chainsaws, saw chains are usually placed with increments of 0.325 inches. The smaller the step in the saw chain, the less vibration it has, but with this decreases productivity, which must be taken into account when buying in a store.

On non-professional domestic chainsaws, saw chains are usually placed with increments of 0.325 inches. The smaller the step in the saw chain, the less vibration it has, but with this decreases productivity, which must be taken into account when buying in a store.

Chains intended for professional work, put in increments of 3/8 or 0, 404 inches. With the use of such a chain, the productivity increases significantly, but so does the vibration. Such chains are used to work on industrial logging.

For frozen and polluted trees, saw blades are used Carbide tipped chains.

The chain pitch is calculated by the distance between two nearby teeth or the length of the segment between two nearby rivets, divided by two. Component parts from chainsaws of different manufacturers can not be combined.

The saw part of the chainsaw consists of an asterisk, a tire and a saw chain. Parts from different manufacturers in this kit are incompatible, due to the incompatibility of technological parameters: the thickness of the leading link and circuit configuration. Therefore, you need to carefully and carefully choose the model of chainsaw. After all, after its acquisition, you will depend on the supply of sets of spare parts of the manufacturer.

It is believed that the performance of the chainsaw is dependent on the shape of the chain, but this is a misconception. In fact, performance is directly dependent on engine power since the more powerful the engine, the more torque is transmitted to the chain.

It is believed that the performance of the chainsaw is dependent on the shape of the chain, but this is a misconception. In fact, performance is directly dependent on engine power since the more powerful the engine, the more torque is transmitted to the chain.

And it depends on the power of the engine how much more it has to pull the chain through the material being cut. As a result, it can be said that the most effective ratio for chainsaws with a powerful motor chain pitch in 3/8 inch

Chain sharpening for chainsaw

Determine that the chain can be sharpened by several features:

- Low speed saw chain in the process.

- The movement of the chain in both directions.

- It becomes small chips from cutting.

Sharpening frequency

There are no definite intervals in time for the saw point, it is simply desirable to undermine it before starting work.

The sharpening of the chain only depends on frequency of its application, you need to carefully monitor whether there are signs indicating that it is time to sharpen.

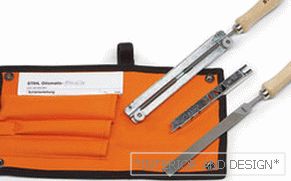

For the process of sharpening the saw chain, special skills are not needed; conventional plumbing tools. For sharpening chains need specially designed tools.

File sharpening

By applying this method, you reduce to minimum cash outlay, due to the fact that there is a file in any household. The main thing is to choose the diameter of the file for sharpening, which is measured by the size of the saw chain. For chains of 1.3 mm, a round file with a diameter of 4 mm is used, and for chains of 1.6 mm a file of 5.2 mm is required. Using a flat file, we adjust the edges of the chain, the saw chain is sharpened at a certain angle, to facilitate this process, there are teeth on the teeth factory notch pointing to the angle of sharpening.

By applying this method, you reduce to minimum cash outlay, due to the fact that there is a file in any household. The main thing is to choose the diameter of the file for sharpening, which is measured by the size of the saw chain. For chains of 1.3 mm, a round file with a diameter of 4 mm is used, and for chains of 1.6 mm a file of 5.2 mm is required. Using a flat file, we adjust the edges of the chain, the saw chain is sharpened at a certain angle, to facilitate this process, there are teeth on the teeth factory notch pointing to the angle of sharpening.

To sharpen the chain, you still need a clamp, to secure and fix the chain, it is installed on the edge of the workbench and the chain is strengthened in it.

Sharpening using a machine

Not all saw chains can be sharpened with file use, it happens when the chain loses the shape of the cutting edges, and the use of a file in this case leads to the loss of a large amount of time. Therefore, in such situations, and justified the use of machines for sharpening chainsaw chains.

There are machines with electric and manual drive they use either a grinding stone or a grinding wheel.

To work on an electric machine, first loosen the screw that clips the chain, insert it into the guide slot. So that the teeth are located in the direction of the grinding wheel. After setting the desired angle can be done sharpening.

To work on a manual grinding machine, you must install desired angle of sharpening, it is determined by the most blunted tooth in the chain.

When grinding, do not grind the teeth too hard, the chain may become less durable from heating and its operation time will decrease.

To consolidate the result obtained from sharpening, blow the sharpened parts with compressed air and lower it into oil for 2–3 hours.

To consolidate the result obtained from sharpening, blow the sharpened parts with compressed air and lower it into oil for 2–3 hours.

The advantages of this method are that when sharpening, you achieve more accurate results, but also lose a lot of time and effort.

When applying for sharpening an automatic machine, you not only sharpen the chain accurately and accurately, but also accelerate the process without wasting your strength.

The machine is made in the form of a small rectangular box. with grinding wheel. You only need to insert a chain to fasten it and turn on the machine. And the chain will start spinning and sharpen itself on a stone.

Sharpening with grinders

For use as a grinding unit grinders, you must have some experience with it, otherwise you can easily ruin the chain. So, if you have no experience with grinderit is better to use other methods. But this method has some advantages:

- It is not necessary to remove the saw chain from the chainsaw during sharpening.

- For sharpening already used used disk for cutting metal with a thickness of 2-2.5 mm.

- When sharpening, the angle is chosen according to your discretion and experience.

- With proper sharpening in this way, the chain can be sharpened. up to 10 times

- The method does not require large financial expenditure and loss of time.

The only drawback is that it is necessary to gain experience and skills by training on a broken circuit.

Video sharpen chain chainsaw

No matter what method of sharpening you choose, be sure to follow all safety precautions, wear protective glasses and gloves. Thanks to these measures you will safely return the chainsaw to your daily work.