The drill - a device that gave a person the opportunity to extract water, oil and gas, has another important purpose - to create holes on the surface of the earth, holes of small diameter and great depth. They need a builder in order to bury in the ground piles and posts, which is attached to the fence. A number of devices, from power lines to individual mailboxes, are mounted on poles buried in the ground. A gardener and a gardener need it for planting cuttings and saplings of trees and for installing the posts necessary for the growth of grapes and some varieties of fruit trees.

The drill - a device that gave a person the opportunity to extract water, oil and gas, has another important purpose - to create holes on the surface of the earth, holes of small diameter and great depth. They need a builder in order to bury in the ground piles and posts, which is attached to the fence. A number of devices, from power lines to individual mailboxes, are mounted on poles buried in the ground. A gardener and a gardener need it for planting cuttings and saplings of trees and for installing the posts necessary for the growth of grapes and some varieties of fruit trees.

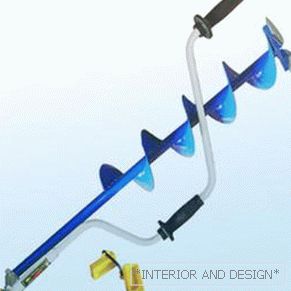

For a lover of winter fishing, a borer is necessary in order to drill a hole in the thick ice covering the winter pond.

Content

- 1 How does the motor drill its principle of operation

- 2 Types of motor-drills

- 3 The main idea - an earthen drill

- 4 Working on a motorbike

- 5 Humor своими руками

- 6 Conclusion

How does the motor drill its principle of operation

Humorы различаются по приводам:

- petrol;

- electrical;

- hydraulic.

Motobur consists of the following elements:

- drive (gasoline engine, electric motor, hydraulic drive);

- transmission (worm or cylindrical coaxial);

- the drill (head, knives) interfaced to the screw;

- extension;

- frame.

Drive is required to create torque forcing the screw with the drill to rotate. Electric engines are low noise and work without exhaust gases, but possess less power and torque relative to gasoline and limited in autonomy by a cord for power supply. Recently, electric drives powered by batteries have appeared.

Drive is required to create torque forcing the screw with the drill to rotate. Electric engines are low noise and work without exhaust gases, but possess less power and torque relative to gasoline and limited in autonomy by a cord for power supply. Recently, electric drives powered by batteries have appeared.

Gasoline and electric motors for high speed and for transmission sufficient power on the auger with the auger it is necessary to lower the speed using the transmission Transmission is worm and cylindrical coaxial. When working you need to ensure that the transmission was filled with oil. The ratio of transmission from 1:25 to 1:50.

The key part of the motor-drill is a drill, coupled with the auger. The drill is a head of small diameter, 7–10 cm long, which is primarily loosens and crushes the soil, which is then cut by a mill, consisting of two symmetrical horizontal knives mounted on the first branch of the auger and equal to it in diameter. Loosened, cut and shredded soil gets on the auger, which is a screw tape, wound on the shaft, and serves to feed the shredded material up from the hole.

The walls of the hole are the outer walls of the screw device. The diameter of the drill head is 30−50 mm, while screw diameter колеблется от 150 до 250 и более. Чем больше screw diameter, тем больше диаметр вырытой лунки, но тем большая мощность и крутящий момент требуется от привода. Шнеки выпускаются различной длины от 1−2 витков до 10 и длиной около 70 см. При необходимости сверления лунки более 1 м используется удлинитель.

Types of mounts

- lungs;

- heavy.

First more compact and cheap. One operator is enough to manage them. They are equipped with an engine capacity up to 3 liters. with. The most common engines with a capacity of 1.5 -2 liters. with. and working volume 33−40 cu. cm.

First more compact and cheap. One operator is enough to manage them. They are equipped with an engine capacity up to 3 liters. with. The most common engines with a capacity of 1.5 -2 liters. with. and working volume 33−40 cu. cm.

Their work is limited to loose sandy soils, loam and black soil. The maximum depth of the hole is 1.5–2 m.

When working with heavy soils, clay, stony soils are used heavy motor drills. They are equipped with engines with a capacity of 3.5 liters. with. and they need two operators to manage them. Some heavy motor-drills are not mounted on the frame, but on the trolley. Then one manager is enough.

Heavy motorized drills can be equipped with a hydraulic drive, which is completed from:

- hydraulic pumpproviding pressure hydraulic fluid;

- hydraulic motor, providing low-speed rotation of the shaft and the drill with the screw;

- distribution systemproviding reverse, by switching the hydraulic fluid supply valves.

Hydraulic drive extremely reliable system as it does not contain a large number of moving moving parts and provides sufficient power and torque to work on large-diameter screws on heavy soils. However, such systems very expensive for non-industrial use without a permanent work front. Heavy motorized drills with hydraulic drive cope with drilling to a depth of 5 m.

The presence of reverse and multiple gears extremely beneficial features for motor drills, as they allow to avoid jamming of the drill with the auger and select the optimal mode of operation.

The main idea is an earthen drill.

Humor происходит от своего предшественника, manual earth drill declared as an invention in the United States as early as 1890, as a machine for “drilling holes for installing mailboxes. Already then the basic principle of work was laid:

- the drill for columns, grinding the soil;

- auger feeding it up from the hole.

The screw, a device well known to us in a mechanical meat grinder, is a screw rotating in a pipe very tightly to its walls, pushing the mass that enters the pipe along the axis.

Ручная бурильная установка состоит из собственно бурильной части (ножи, сверло), шнекового механизма подъема грунта, рукоятей для создания крутящего момента мускульной силой. Humor заменил мускульную силу torque moment created by the drive.

Working on motorbike

In order to drill the hole, the operator, holding the control knobs, sets a motor drill vertically to the point where the hole is supposed to be located and turns on the engine. The head of the drill deepens, the mill starts cut the soil and the motor drill is sinking. For better performance, you need to periodically pull it up to release excess soil in the screw.

In order to drill the hole, the operator, holding the control knobs, sets a motor drill vertically to the point where the hole is supposed to be located and turns on the engine. The head of the drill deepens, the mill starts cut the soil and the motor drill is sinking. For better performance, you need to periodically pull it up to release excess soil in the screw.

The optimal depth of the resulting well limited by height to which the operator can lift the device to remove it from the hole and is 1-1.5 m.

The disadvantage of the motor-auger is that when a drill is jammed when it hits a stone, the motor-drill can make a sharp reverse rotation. The operator may be injured. Therefore, some motor-drills (for example, Hitachi firms) equipped with a protective apron, mounted on the frame of the motor-drill and with a special limiting lever, emergency shut-down of the engine when jamming and beginning of the reverse rotation. Working with a motor-drill requires the attentive attitude of the operator to safety engineering and considerable efforts to keep the motor-drill.

Humor своими руками

Prices for the most budget motorized drills begin from 10 000 rub. With the well-known skills of the metal repair work, you can build a motor-drill from a chainsaw or a powerful electric drill.

In the case of using chainsaw you will need:

- gearbox reducing the rotation speed of the shaft, which can be purchased separately;

- sleeve for connecting the motor shaft with the shaft of the gearbox;

- the drill with the screw which can also be bought in addition.

Making a motor-drill on the basis of a powerful (2 kW) perforator is even simpler, since there is in the punch built-in gear and the security system when jamming and connecting to the drill does not require additional devices. The situation is similar with the drill, with the difference that an additional gearbox and a transition sleeve will be required.

Making a motor-drill on the basis of a powerful (2 kW) perforator is even simpler, since there is in the punch built-in gear and the security system when jamming and connecting to the drill does not require additional devices. The situation is similar with the drill, with the difference that an additional gearbox and a transition sleeve will be required.

Of course, you can as drill heads use a drill 30−50 mm length 7−10 mm, which is welded to the meter segment of the pipe, the internal diameter of which corresponds to the diameter base drill.

For the manufacture of the screw, it is necessary sweep pattern which can be found on the Internet, but coiling and welding the strip, cut from steel sheet, is so laborious that it is better to buy ready-made.

The economy of the process of manufacturing motor tools plays an important role. Before plunging into the manufacturing process, estimate order of costs (gearbox, milling cutter, coupling, auger). Perhaps the price will be close to buying a budget option.

Recently it went on sale (about 4500 rubles). nozzle MB-1 suitable for installation on chainsaws Husqvarna, Stihl and some Chinese manufacturers, which allows you to attach a drill with a screw to a chainsaw and thus get two tools in one, a chainsaw and a motor drill.

When working with a self-made motor drill, remember that this is not a fully-fledged tool and limit the diameter of the drilling hole to 150 mm

Conclusion

A motor-drill is an indispensable device where it is necessary to drill a hole with a diameter of 10 to 25 cm and a depth of up to 2 m. Working with a motor-drill is traumatic and requires increased safety measures. Making a lightweight motorbike on the basis of a chainsaw or a punch is possible, but it requires considerable skills, and the purchase of additional parts can make the process economically impractical.